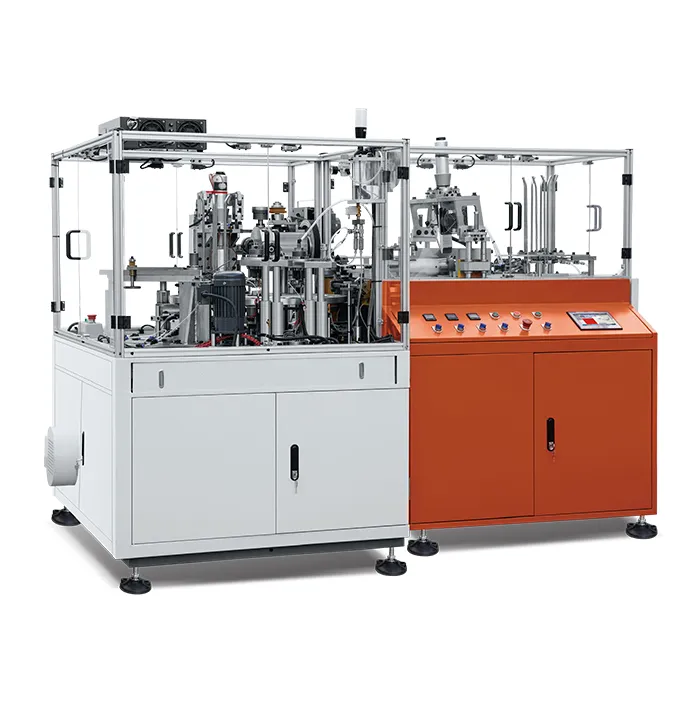

ZGJ-IV Intelligent Paper Lid Machine is mainly used for the production of paper cup lids with paper cup diameter less than 10omm, and can design the corresponding drinking holes according to customer needs.

- Max. top diameter: 100mm

- Max. height: 25mm

- Production speed: 100pcs/min

- Air consumption: 0.6 m³/min