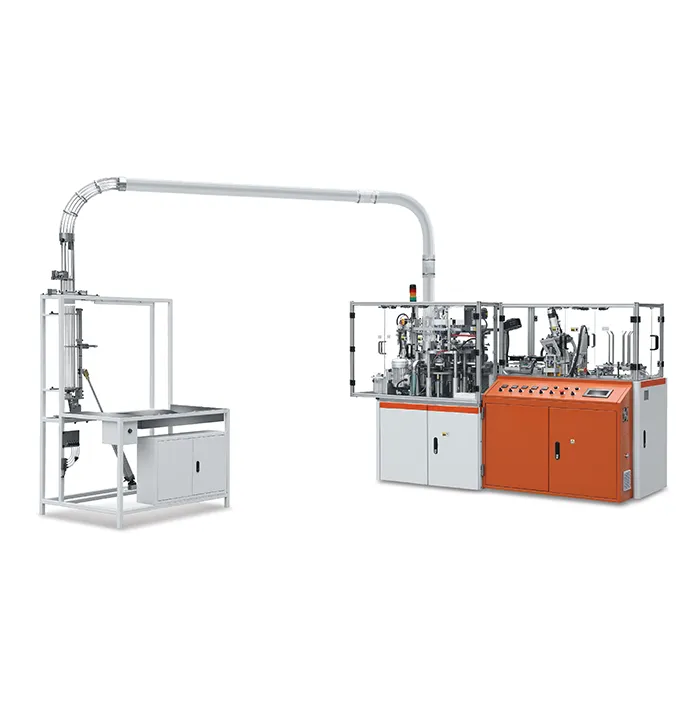

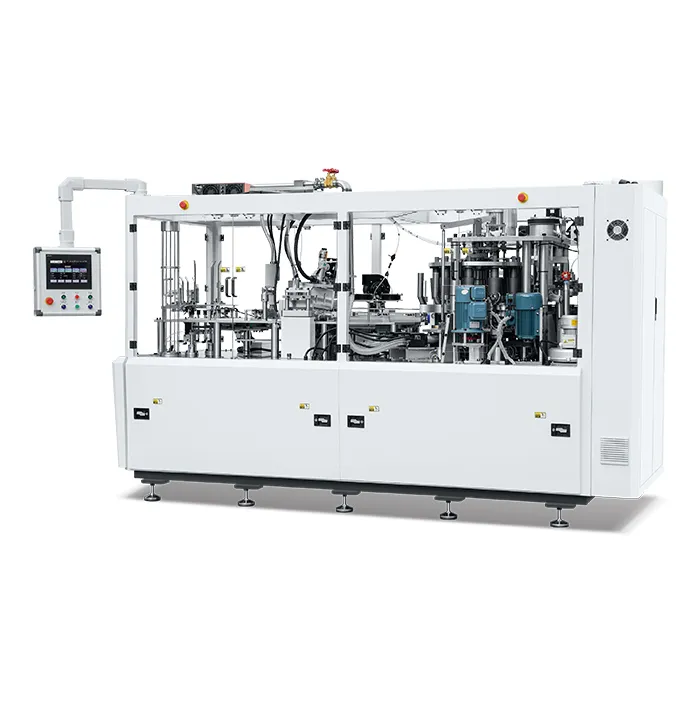

From espresso cups to large takeaway cups, paper cups are available in a range of sizes to meet different needs while also offering logo and branding customization options, ideal for cafes, restaurants and events. Paper cups are lightweight, convenient and easy to use, meeting the goals of sustainable packaging. Demand for paper cups is growing in regions such as Europe and North America, where environmental regulations are strict, as well as in Asia Pacific, where environmental awareness is growing.

Paper Cup