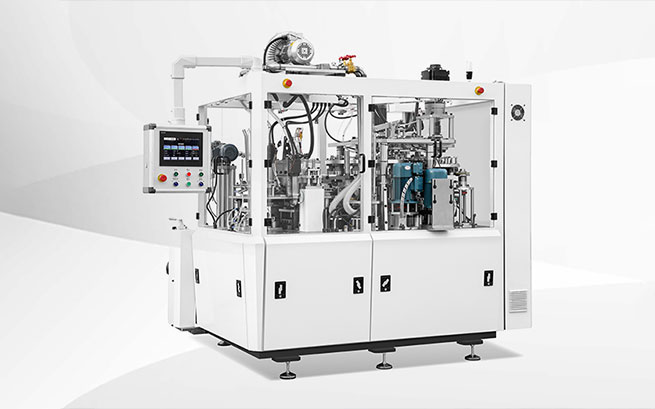

Discover Paper Lid Forming Machine: The Ultimate Leak-Proof Guarantee for Your Brand. Engineered to eliminate production bottlenecks and customer complaints, our fully automatic lid former delivers precision-crimped, perfectly sealing lids at unmatched speeds. With an industrial-grade PLC control system and patented crimping technology, it ensures zero-defect output, seamless line integration, and dramatically reduced operational costs. For packaging manufacturers who cannot compromise on quality, the Discover machine is the definitive solution to protect your reputation and maximize your ROI.

1. Dual Open-Type Cylindrical Cam Drive Mechanism

2. Integrated Continuous Spray Lubrication System

3. Swiss Leister Bottom Air Heating System

-

The bottom heating process utilizes a Swiss Leister air heater, providing fast, uniform, and reliable heat for perfect cup base formation.

4. Linear Guide Paper Sheet Conveyor System

-

The paper sheet feeding and conveyance employ a linear guide system, guaranteeing smooth, precise, and low-friction transfer of materials.

5. Rigid Unibody Machine Base Frame

-

Constructed with an integral, one-piece base, the machine achieves exceptional structural integrity, minimizing vibration and maintaining alignment for consistent performance.

6. Precision Gear Transmission System

-

Power is transmitted through a high-precision gear drive system, ensuring efficient, stable, and low-noise operation throughout the production cycle.