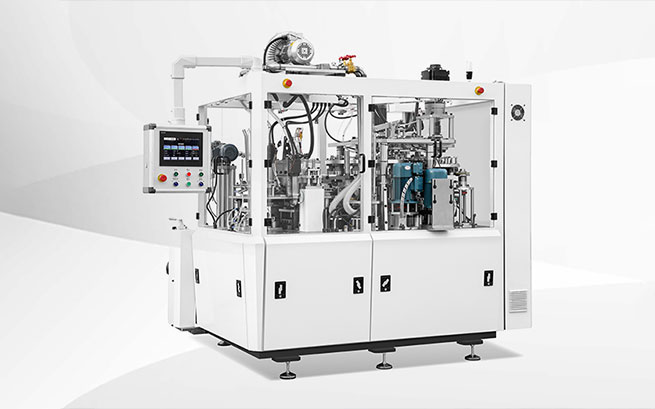

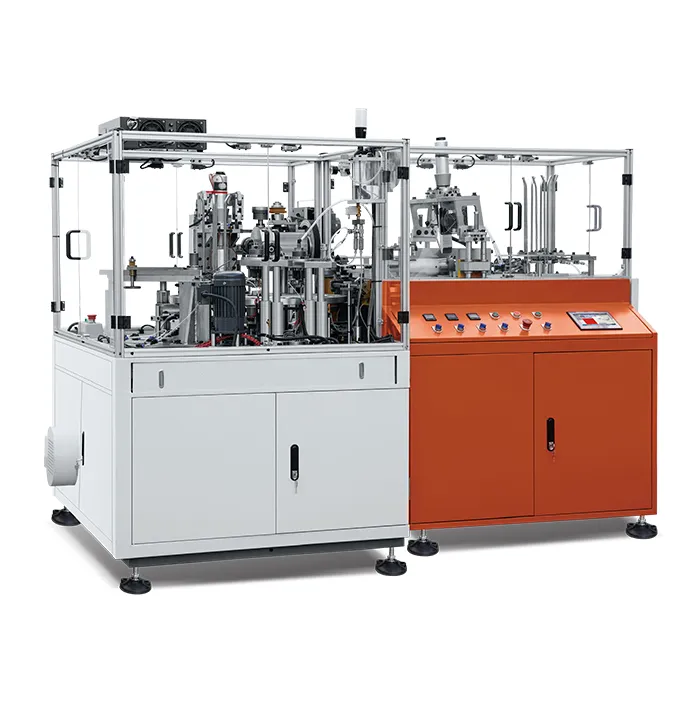

Equipped with a state-of-the-art PLC control system, the ZGJ-IV paper lid forming machine delivers a fully automated operation, minimizing manual labor and maximizing efficiency. Its advanced features include:

· Automatic Paper Feeding System: Ensures smooth and accurate material input, reducing waste.

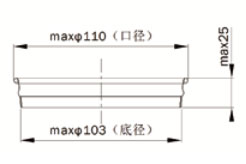

· High-Precision Cutting and Sealing: Guarantees uniform lid dimensions and a perfect fit for cups.

· Touchscreen Interface: Offers an intuitive user experience with easy adjustments for different lid sizes and designs.

By integrating these advanced automation technologies, the machine significantly increases production speed and consistency.