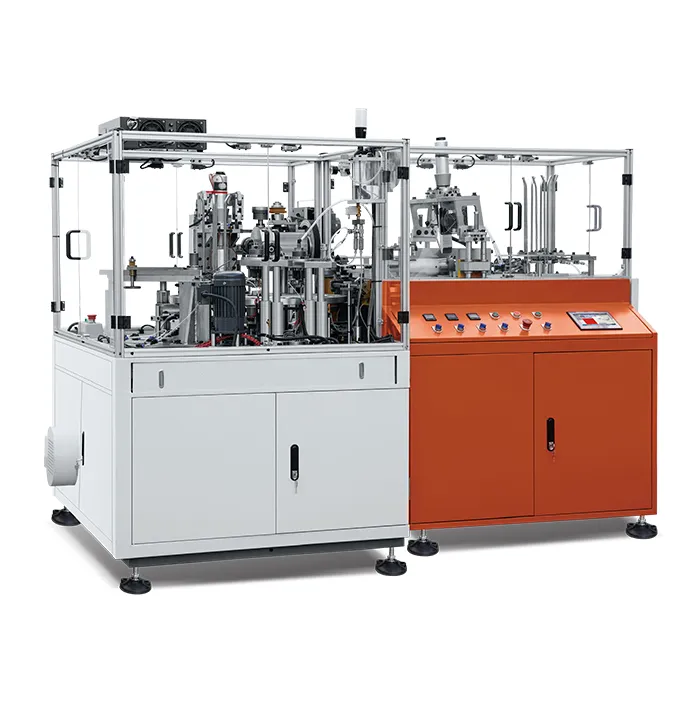

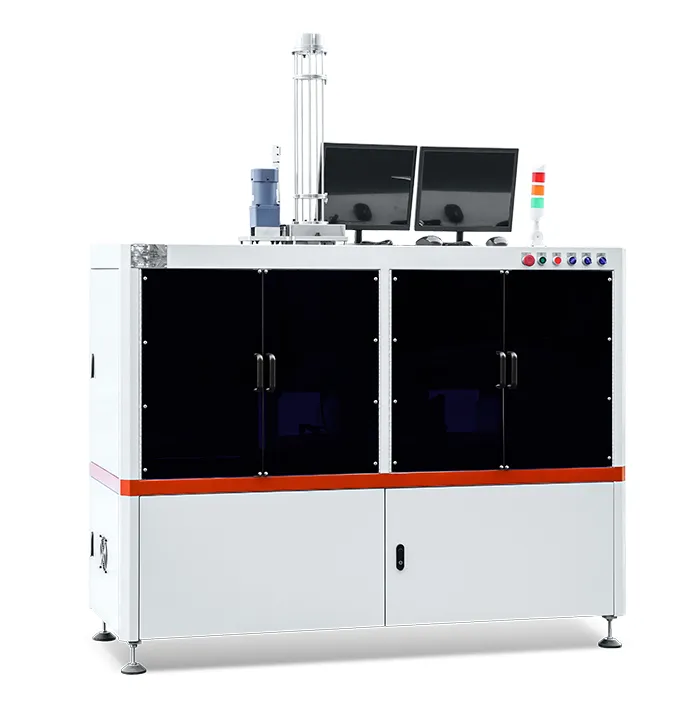

Equipped with an intelligent PLC control system, the ZGJ-Ⅲ lid paper cup machine product offers a fully automated process, significantly reducing labor costs while increasing production efficiency. Key automation features include:

· Automatic Paper Feeding: Ensures smooth and consistent material input, preventing misalignment.

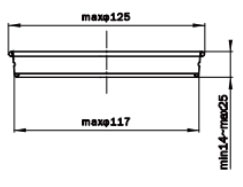

· High-Precision Cutting System: Delivers accurate lid dimensions for a perfect fit.

· User-Friendly Touchscreen Interface: Allows easy adjustments for different lid sizes and thicknesses.

By streamlining the entire production process, this machine enhances output efficiency and minimizes material waste.