01

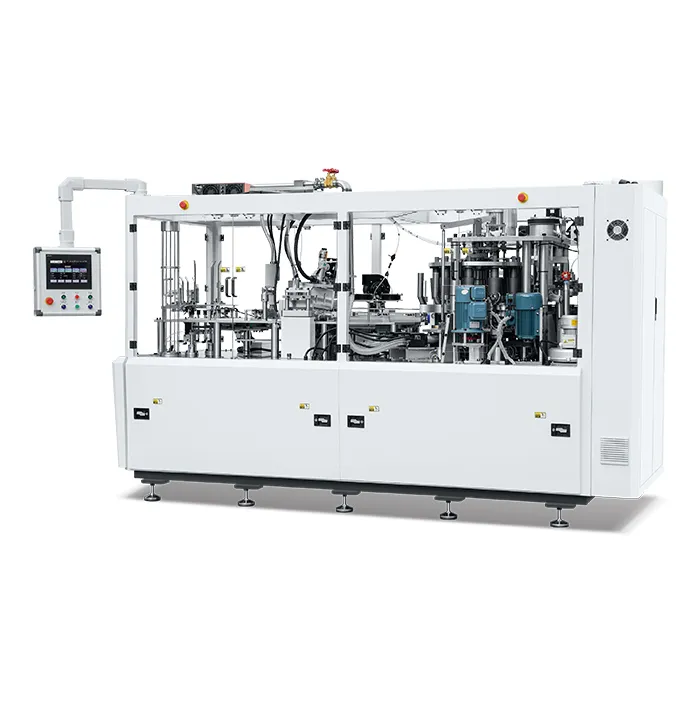

Integrated Leaf Mold Frame

This design reduces the risk of mold loosening and misalignment, improves production efficiency, and extends equipment service life.

02

Single Manipulator Cup Removal

It can quickly and accurately remove formed paper bowls from the mold, avoiding instability caused by multi-arm operations, and effectively reducing downtime during production.

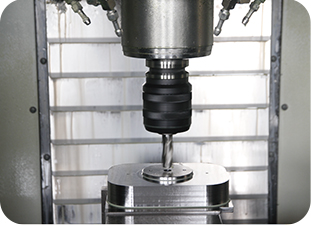

Utilizes a high-precision gear drive system to provide stable power output, ensuring smooth machine operation and low noise levels.

04

Open-Type Indexing Box

The open-type indexing box design makes the drive system more accessible and easier to maintain, allowing users to conveniently inspect and repair components.

05

Bottom Leister Heating

This heating method is efficient and energy-saving, optimizing energy usage and improving production efficiency.

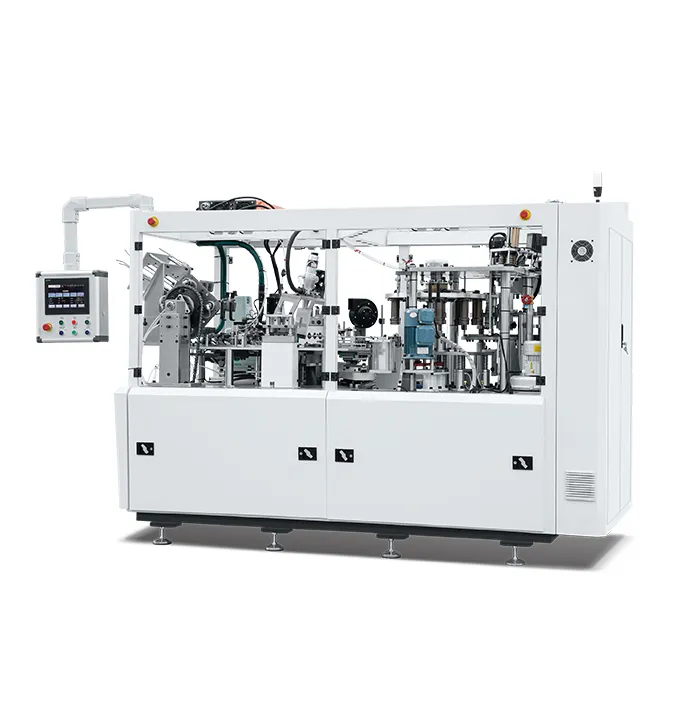

06

Integrated frame design

The double-layer paper cup machine features an integrated frame design, offering enhanced load-bearing capacity and stability.