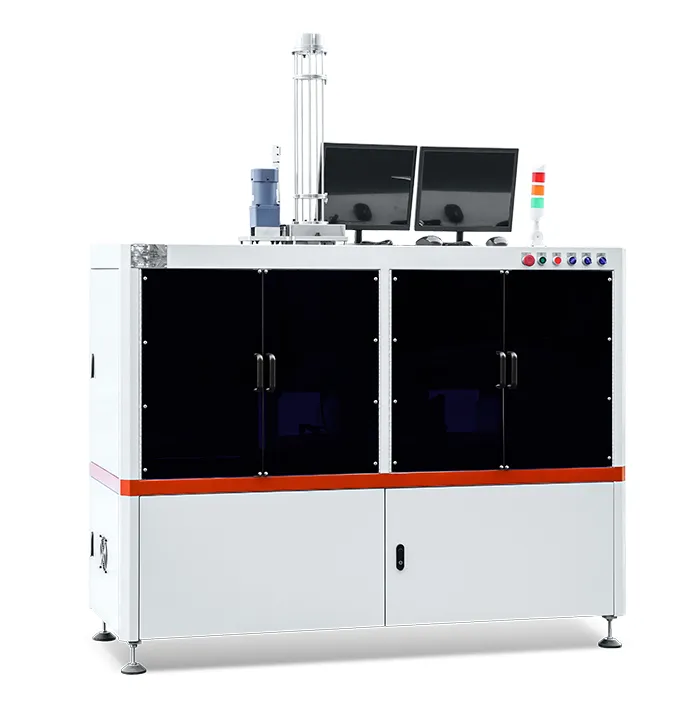

High-Precision Defect Detection

The paper cup inspection machine utilizes state-of-the-art sensors and advanced optical systems to inspect each paper cup or container thoroughly. These sensors are designed to detect even the most minute defects, such as irregularities in shape, poor sealing, size discrepancies, and surface imperfections. This precision ensures that only cups meeting stringent quality standards make it to the final packaging stage.

Advanced Optical and Laser Technology

Equipped with high-resolution cameras and laser detection technology, the machine is capable of performing in-depth visual inspections. These systems work in tandem to detect issues such as wrinkles, holes, tears, and misalignments, which are critical for ensuring that the final product meets the necessary specifications.

Real-Time Defect Analysis

The inspection process is entirely automated, offering real-time data analysis. This means that any defective cups are immediately flagged and removed from the production line, minimizing waste and ensuring that only products of the highest quality proceed to the next stage of production.

Dimensional Accuracy

One of the most crucial aspects of paper cup manufacturing is maintaining strict dimensional accuracy. Our Intelligent Paper Cup/Container Paper Cup Inspection Machine uses precise measurement systems to check the height, diameter, and overall structure of each cup. This level of measurement ensures consistency in product size, which is essential for the proper fit of lids or compatibility with automated filling machines.

Automated Sorting and Rejection System

Once the inspection is complete, defective cups or containers are automatically rejected via an efficient sorting mechanism. Using air jets or mechanical arms, faulty items are ejected from the line, ensuring that they do not proceed to the packaging stage. This feature significantly reduces human error and increases overall production efficiency.

Seamless Integration with Existing Lines

Designed for ease of use, the paper cup inspection machine integrates effortlessly into your existing production line. It works with various automated systems, including cup stackers, conveyors, and packaging equipment, to streamline operations without disruption.

High-Speed Operation

Our inspection machine is built to handle high-speed production lines, ensuring that even at maximum output, the inspection process remains accurate and efficient. It can inspect hundreds or even thousands of cups per minute, making it ideal for large-scale production environments.

User-Friendly Interface

The machine features an intuitive, easy-to-use interface that allows operators to quickly adjust settings, monitor performance, and review inspection reports. The clear, digital display and straightforward controls ensure minimal training time and efficient operation.

Durability and Reliability

Manufactured with high-quality materials, our inspection machines are designed for longevity. Built to withstand the rigors of continuous, high-speed operations, they are durable and require minimal maintenance, helping to reduce downtime and lower long-term operational costs.

Competitive Pricing and Support

As China paper cup inspection machine suppliers, we are committed to providing our clients with not only state-of-the-art machinery but also affordable pricing options. We offer a competitive paper cup inspection machine quotation tailored to your specific needs, ensuring that you get the best value for your investment. Additionally, our dedicated customer service team is always ready to provide support, from installation to ongoing maintenance.

Conveying and positioning devices

It is composed of conveyor belts, rollers, etc., which are used to convey the paper cups through the detection area in turn at a certain speed and spacing to ensure that the paper cups can reach each detection position stably and accurately.Through the sensor, the paper cup is accurately positioned, and the paper cup is in a fixed position during image acquisition and detection, so as to improve the accuracy of detection.

Image acquisition section

Equipped with a professional industrial camera, it is the core component of image acquisition, with the characteristics of high resolution and high frame rate, which can quickly and clearly capture the image information of the paper cup and provide clear image data for subsequent analysis.

Remove the mechanism part

It is composed of cylinders, electric push rods, etc., and when the unqualified paper cup is detected, the control system will issue an instruction to remove the unqualified paper cup from the conveyor belt through the actuator to ensure that the qualified product enters the next process.