DISCOVER 30 years of precision engineering and manufacturing, producing 10,000 bowls per minute with consistent quality. Nano-welded construction achieves 99.8% leak-proof performance, while dual-roll pressing technology enhances collapse resistance by 40%. Intelligent energy-saving technology reduces energy consumption by 35%, ensuring production stability from the very start!

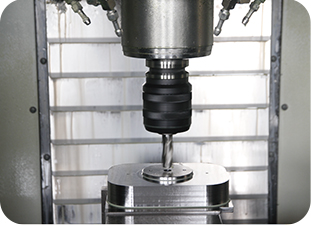

1. Surface hardness can reach approximately HV500

2. Thickness is 25-250 microns

3. Breakdown voltage can reach 2000 volts

2. Heat sealing cup synchronization deviation <0.1 seconds

3. Wear resistance increased by 3 times

2. Temperature control accuracy ±1℃

3. Preheating time reduced to 90 seconds

2. Oil change cycle extended to 6000 hours

3.Lubricant consumption reduced by 70%

2. Noise reduced to 75 dB

3.Energy consumption reduced by 35%