The packaging and packing design of paper cups has many significant advantages. First, the use of professional packaging methods can effectively protect paper cups during transportation, reducing damage caused by collisions or pressure. In addition, customized packaging solutions can be adjusted according to specific customer requirements, providing flexible options to ensure the integrity and market competitiveness of paper cup products.

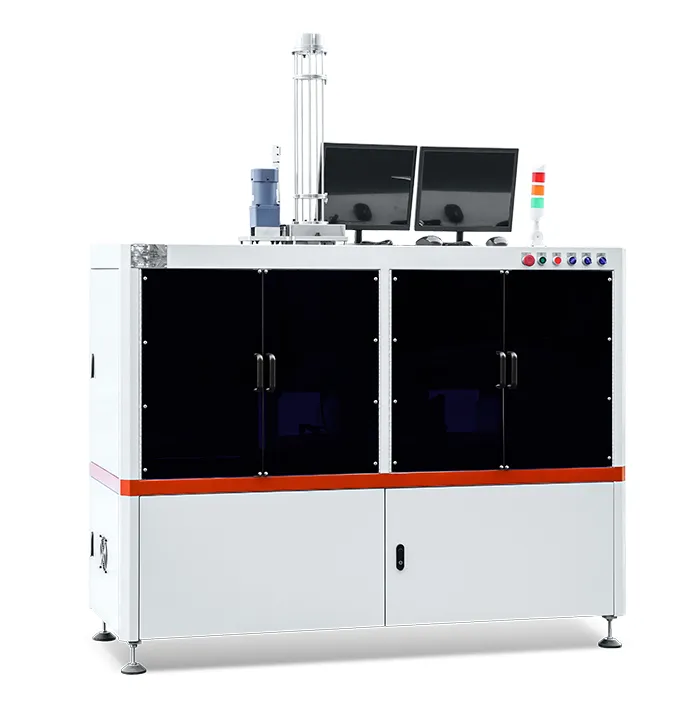

Ancillary