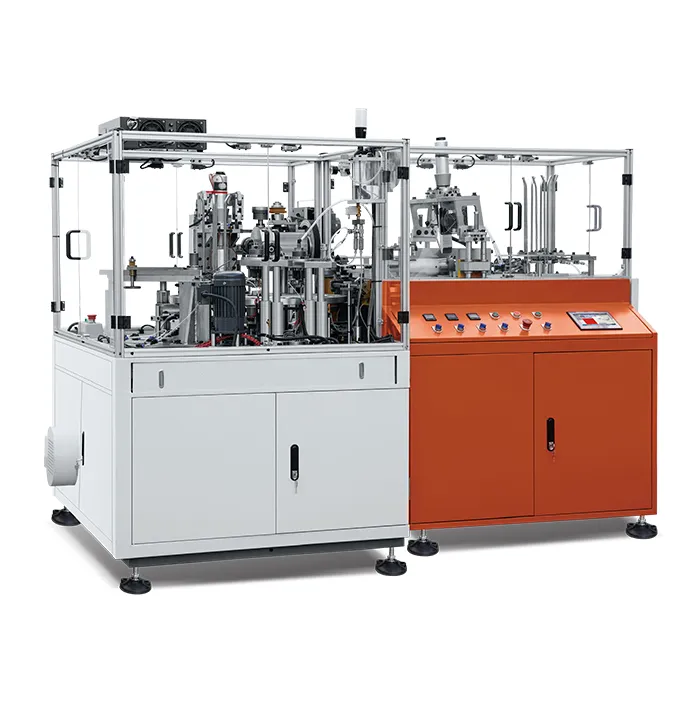

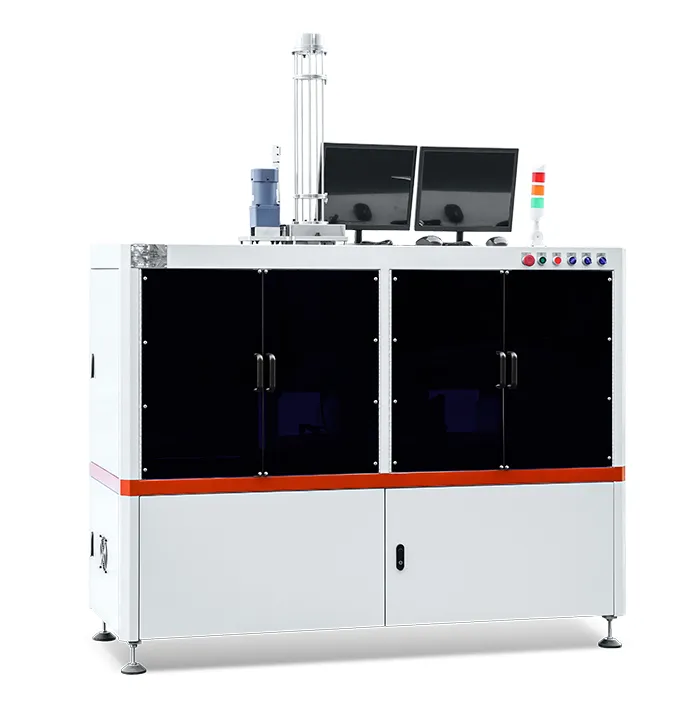

Paper cup rim flattening machine is an optional equipment of paper cup forming manufacturing line, which is mainly used to press finished forming cup into square cup.

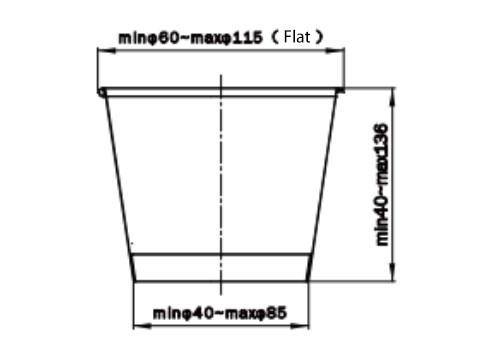

- Max. top diameter: 115mm

- Max. height: 136mm or less

- Production speed: 80-90pcs/min

- Air consumption: 0.3m³/min