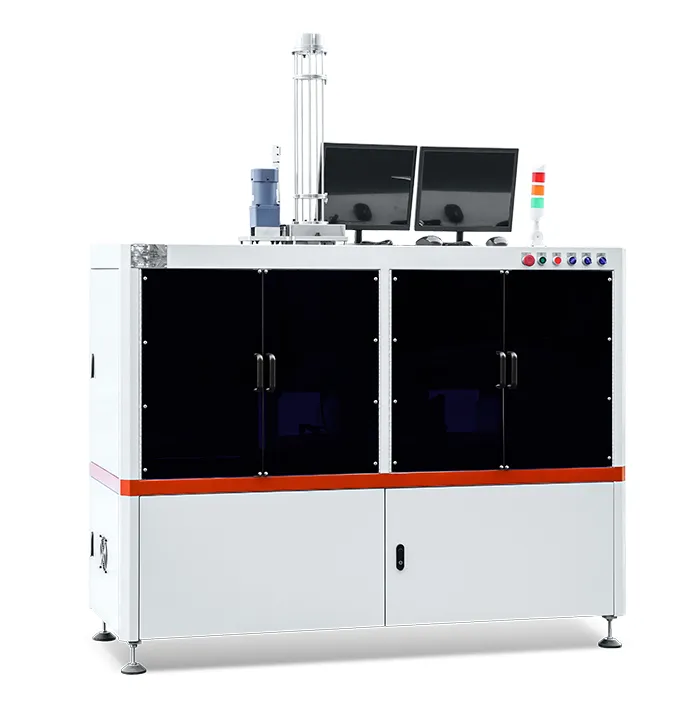

Automatically collect and count formed cups as well as pack stacked cups into plastic film and finish closure automatically.

- Packing speed: 15lines/min

- Packing in diameter: 90mm-150mm

- Packing in length: 350mm-700mm

- Film thickness: 15UM-40UM

Precision

Efficiency

Cost-Effectivenes

Automatically collect and count formed cups as well as pack stacked cups into plastic film and finish closure automatically.

Discover Machinery's is a trusted provider of advanced packaging solutions, offering high-speed and precision-engineered paper cup packing machines to streamline your production line. Designed to enhance efficiency and accuracy, our machines provide a fully automated packaging process, reducing labor costs while increasing productivity. Whether you need to pack small or large batches, our equipment ensures consistent results, making it the ideal choice for businesses in the food and beverage industry.

As an optional equipment in the paper cup manufacturing line, automatic paper container counting packaging machine can automatically collect and count forming paper cup and then package the stacking paper cups in a plastic film and sealing finally. The kind of paper cup packaging machine is applied to package all kinds of disposable paper cup and disposable paper bowl. The packaging speed is up to 15 bags/min. Besides, the paper container packaging machine can connect four paper cup forming machine at the same time and can convey product to designated spot by conveyor according to the requirement of customers.

| Packing speed | 15lines/min |

| Packing in diameter | 90mm-150mm |

| Packing in length | 350mm-700mm |

| Packaging film thickness | 15UM-40UM |

| Net weight | 800kg |

| Power supply | 380V |

| Rated power | 4.5KW |

| Air consumption | 0.1m³/min |

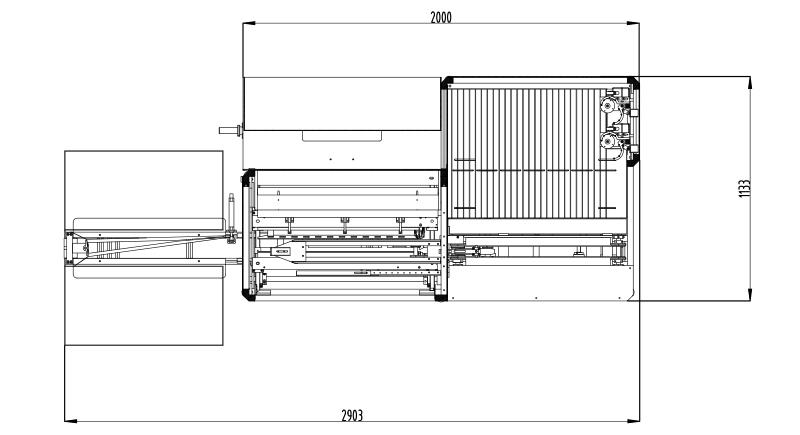

| Dimension |

L2000mm*W1130mm*H1870mm Add a conveyor belt L2870mm*W1130mm*H1870mm |

|

|

Our paper cup machine service is supported by a dedicated team of professionals, from providing pre-sales advice and customizing machines to meet specific production requirements, to providing ongoing post-sales support and guidance.

Our paper cup machine service is supported by a dedicated team of professionals, from providing pre-sales advice and customizing machines to meet specific production requirements, to providing ongoing post-sales support and guidance.