Paper cup lids are mainly used to prevent spills, keep drinks warm, and make them easier to carry. They effectively prevent liquid leakage, ensuring the safety of takeout drinks. At the same time, the lid design helps maintain the temperature of the drink, reducing heat loss and enhancing the customer's drinking experience.

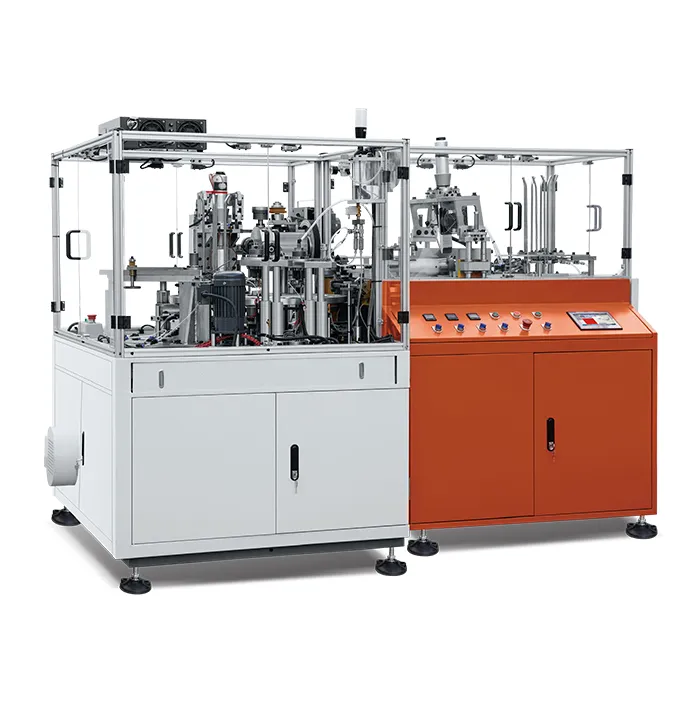

Paper Lid