Solving Your Core Production ChallengesHow can beverage manufacturers increase output while reducing operational costs? The KSJ-160 paper tea cup machine delivers 160 cups/minute with 21kW power consumption - 30% less energy than conventional models. Industry data shows automated systems recover investment within 14 months through reduced labor and waste. For tea brands facing seasonal demand spikes, this automatic cup making machine maintains consistent quality even at maximum 350gsm paperboard capacity.

Engineering Excellence in Cup Formation

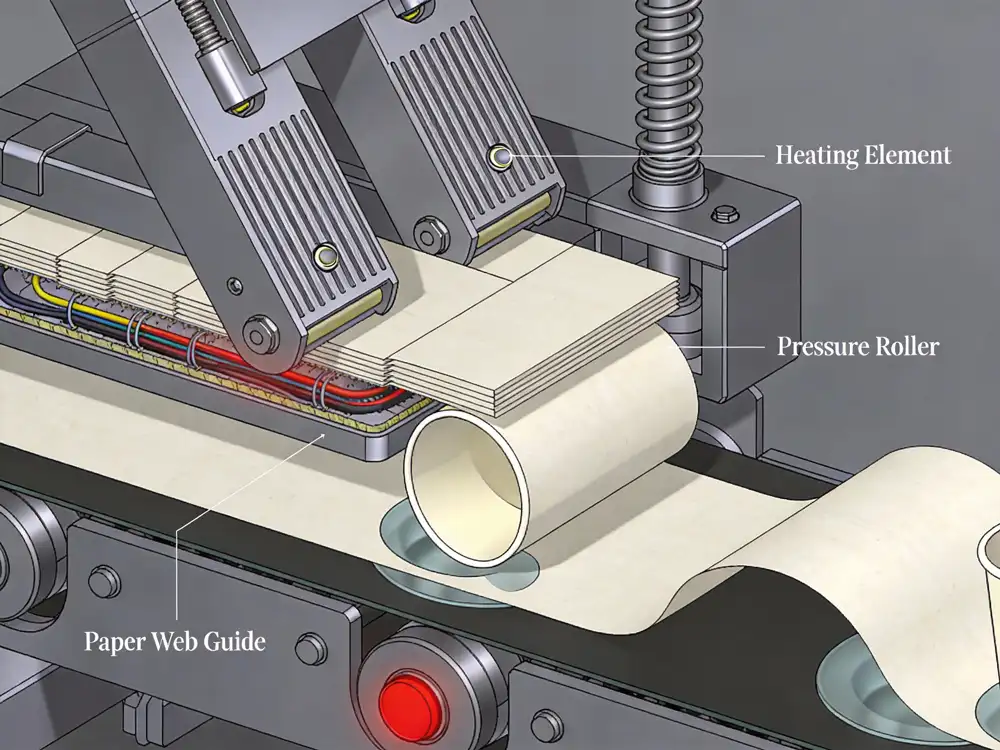

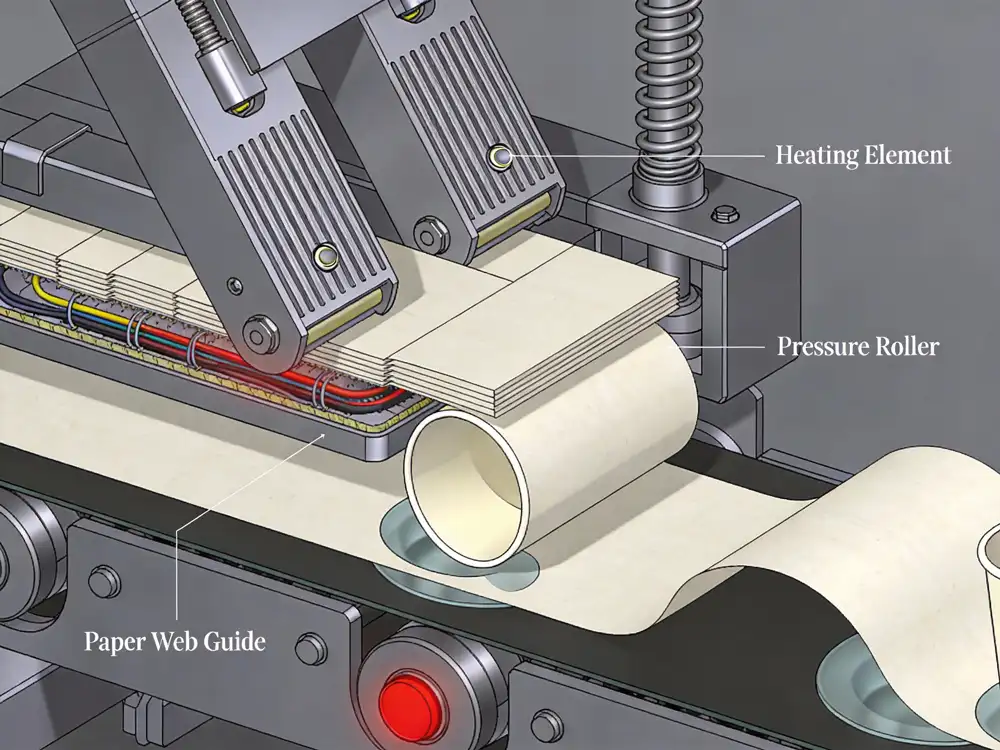

The secret lies in its Open Cam Drive with Double Longitudinal Axis technology. Unlike chain-driven competitors, this system achieves:

- Zero-clearance motion transmission for vibration-free operation at 160 cups/minute

- Leister bottom heaters maintaining ±1°C temperature accuracy for perfect seals

- Linear guide rails eliminating paper jams even with thick 350gsm stockThird-party tests show 99.8% seal integrity - critical for hot tea applications where leakage means brand damage. The automatic spray lubrication system extends maintenance intervals to 500 operating hours, slashing downtime by 45% compared to manual lubrication models.

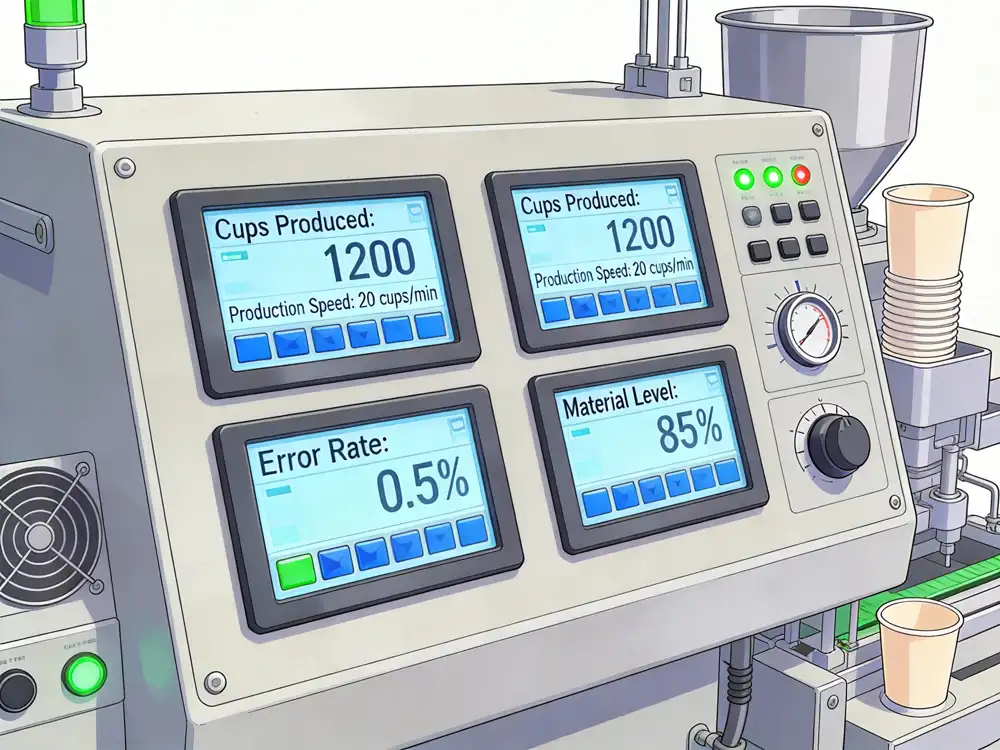

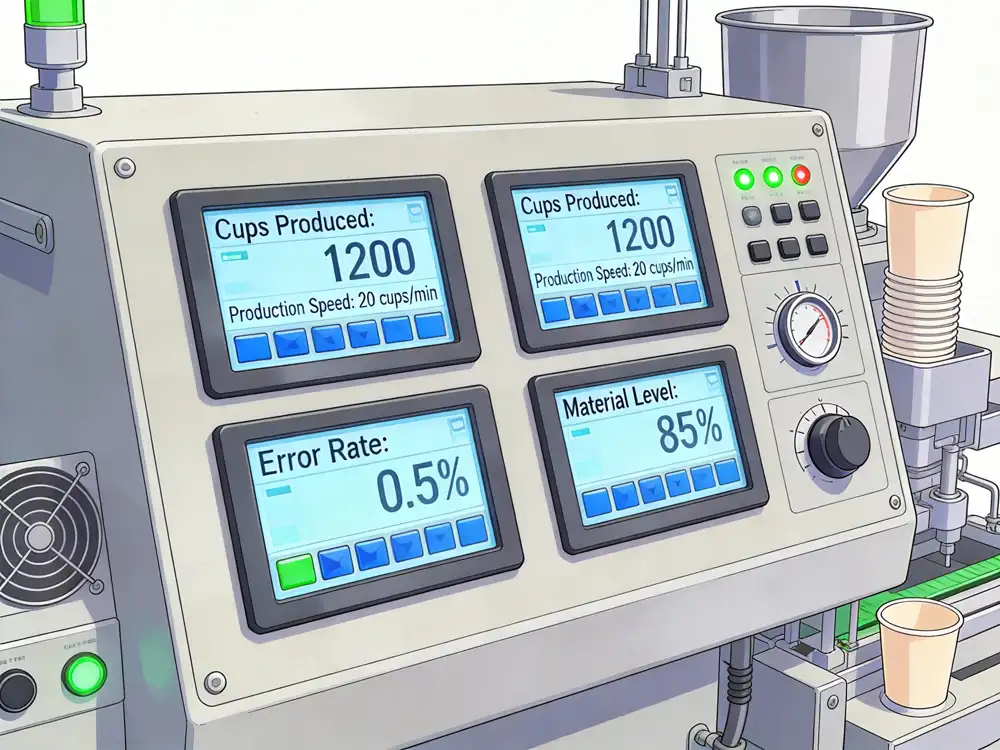

Smart Automation for Real-World ProductionModern factories need more than speed - they need intelligence. The KSJ-160's control system features:

- Touchscreen HMI with recipe memory for 12 cup sizes (2-16oz)

- Real-time OEE tracking measuring performance, availability, and quality

- Predictive maintenance alerts based on vibration and temperature sensors

- A Mumbai-based tea company reported 22% higher throughput after switching to this system, with changeovers between cup sizes taking under 15 minutes. The machine's IoT readiness allows integration with packing lines and laser coders, creating a seamless paper cup production line from blank to boxed product.

Sustainability Meets Brand CustomizationWith global plastic bans accelerating, eco-friendly packaging machinery isn't optional. The KSJ-160 handles PLA-coated papers for compostable cups while maintaining production speeds. Brand differentiation features include:

- Hot foil stamping units for premium metallic logos

- Edge coloring systems for signature cup rim treatments

- Variable wall thickness for thermal insulation optimization

- Bubble tea chains particularly benefit from the φ30-75mm base diameter flexibility, creating signature cup shapes that stand out in social media visuals. The machine's quick-change tooling accommodates seasonal promotions without production pauses.

Maximizing Your Investment ProtectionBeyond the machine itself, operational support determines long-term ROI. Discover Machinery provides:

- On-site commissioning with 72-hour production validation

- Augmented reality troubleshooting via smart glasses for instant technician support

- Spare parts guarantee with critical components stocked globallyA documented case study showed a 3,200% ROI over 5 years for a Kenyan tea cooperative, attributed to the machine's 98.5% uptime and local technical support.

Your Next Step in Production EvolutionReady to transform your cup manufacturing? The KSJ-160's combination of German-engineered precision and adaptable automation makes it the industry benchmark. Request a live production demonstration to see how 30-second changeovers and IoT integration can future-proof your operation. Visit our paper tea cup machine product page for technical specifications and financing options.