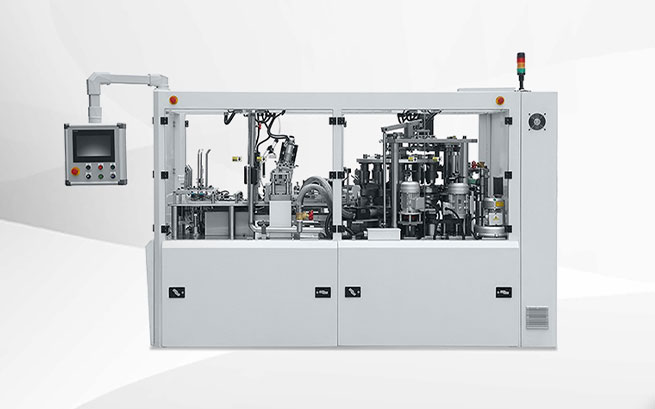

Discover Machinery's FWJ-IV Intelligent Rectangular Paper Bowl Machine is an advanced solution for efficient, high-quality rectangular paper bowl production. As a tech leader, it boosts productivity, ensures quality, and delivers long-term reliability. Driven by Double open type Cylindrical Cam, it enables stable operation. The Uninterrupted integral spray lubrication system reduces wear for durability. Equipped with Swiss Leister air heater for bottom heating, it guarantees consistent heating quality. Its integral machine base and linear guide-equipped paper conveyor enhance operational smoothness, fully meeting modern food packaging industry demands.

- Paper bowl size: 170*120mm

- Production speed: 55-70bowl/min

- Paper gram weight: 210-350gsm

- Paper type: Single PE or double PE