What's the most cost-effective solution for starting a paper cup manufacturing business? The answer lies in choosing the right paper cup machine that balances production speed, material versatility, and operational costs. With the global disposable packaging market projected to reach $105.3 billion by 2025 (Smithers Pira), investing in efficient cup-making equipment has never been more critical. I've seen firsthand how selecting the wrong machinery can cripple profitability - but when matched correctly to business needs, these industrial workhorses become profit engines.

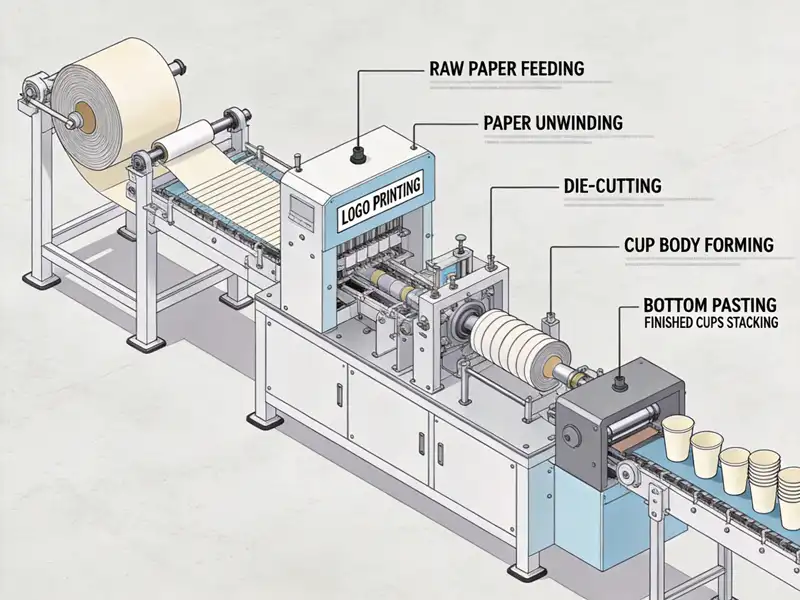

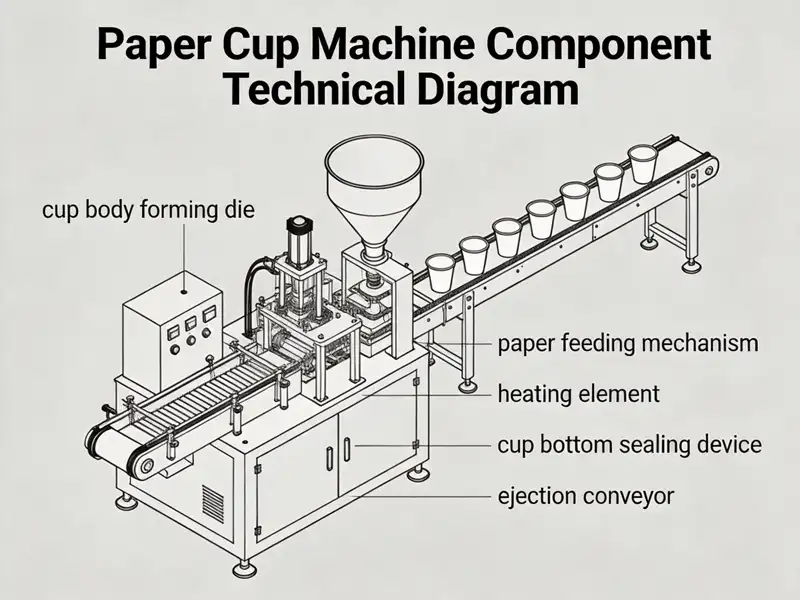

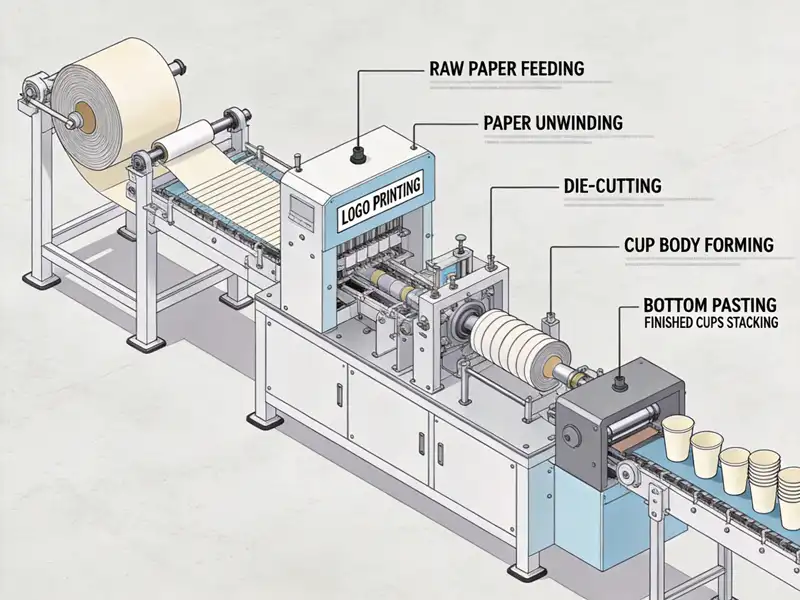

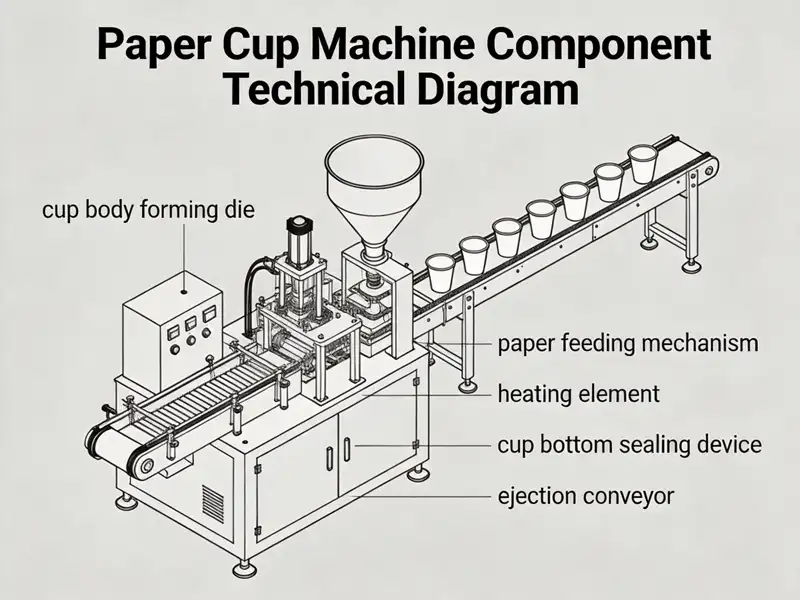

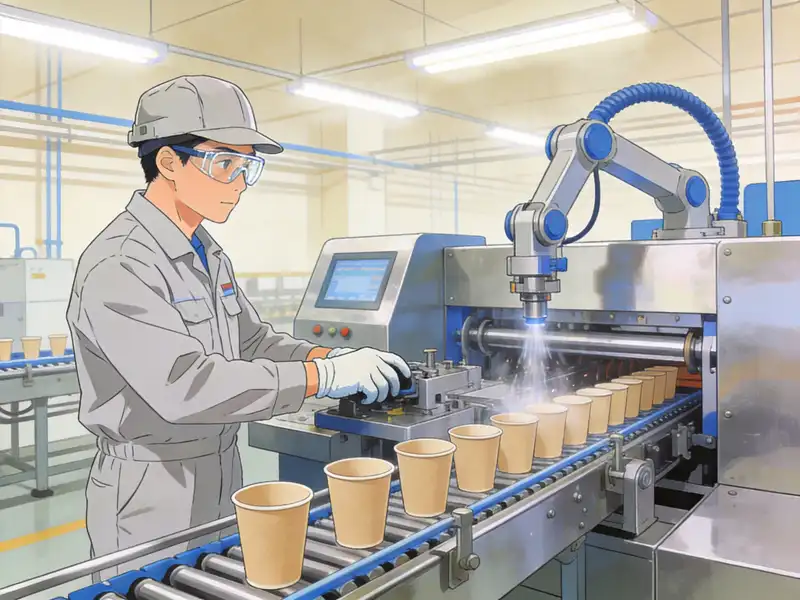

Modern paper cup machines transform PE-coated paper rolls into finished products through a sophisticated sequence: unwinding, side sealing, bottom punching, base attachment, rim curling, and ejection. The Discover Machinery ZSJ-Ⅲ model exemplifies this process with its three-holed robotic arm that precisely handles 60-80 cups per minute. What impresses me most is the Open Cam Drive system - this double-axis mechanism delivers exceptional stability at high speeds, reducing vibration-related defects that plague cheaper models.

During my visit to a Seattle-based cup manufacturer, their production manager highlighted how automatic lubrication systems cut their maintenance costs by 40% compared to manual alternatives. The continuous oil spray on moving parts significantly extends component life - a crucial consideration when calculating total ownership costs. For businesses processing biodegradable materials like PLA-coated paper, temperature-controlled Leister bottom heaters ensure consistent sealing without compromising eco-friendly properties.

Production Capacity and Machine Specifications

Paper cup machines aren't one-size-fits-all solutions. Production speeds vary dramatically:

- Low-speed models: 30-45 cups/minute

- Medium-speed (ZSJ-Ⅲ): 60-80 cups/minute

- High-speed (KSJ-120E): 100-120 cups/minute

The KSJ-120E series stands out with its integral rack design and extrusion bottom molding technology. When testing this equipment, I observed how its gear transmission system maintains ±0.5mm dimensional accuracy even at maximum throughput - critical for clients like national coffee chains with strict cup specifications.

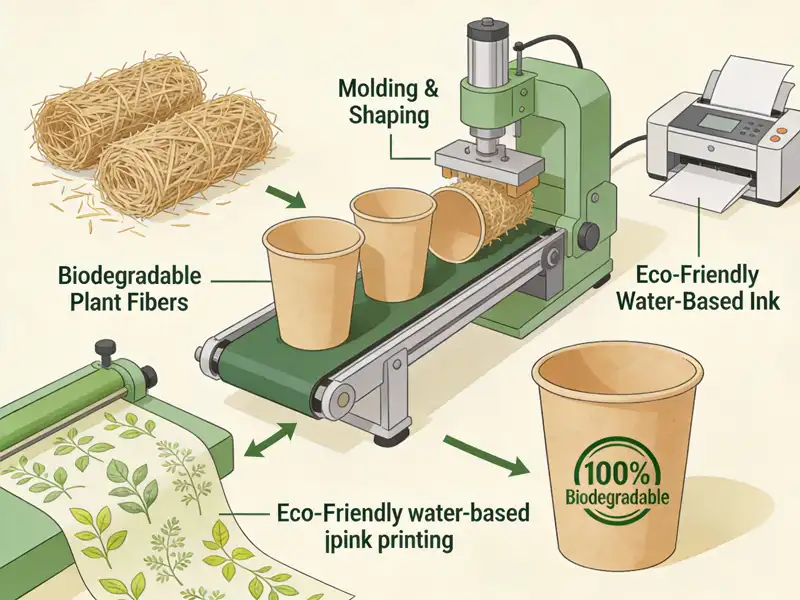

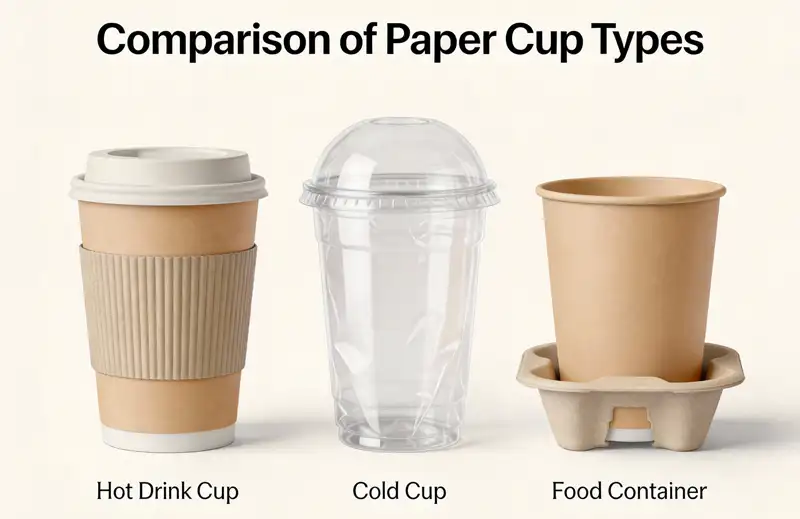

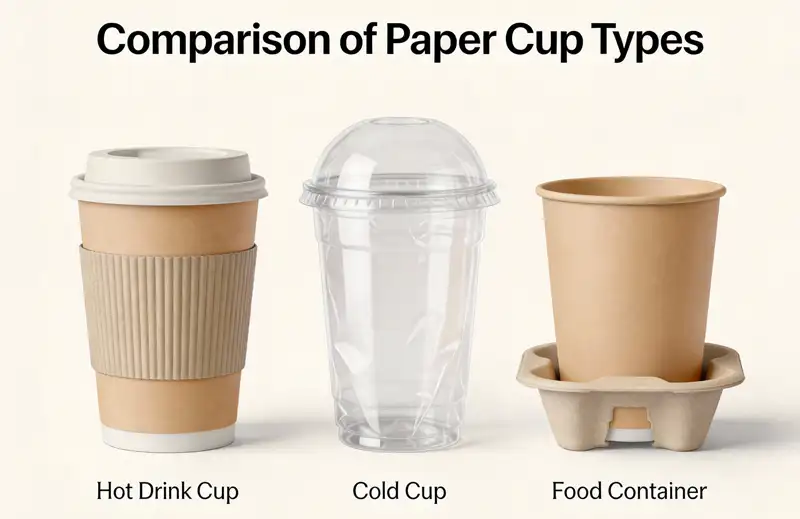

Material versatility is another key differentiator. While basic machines handle standard 210-350gsm PE-coated paper, advanced models like those from Discover Machinery process everything from lightweight ice cream cup stock to heavy-duty soup container materials. The real game-changer? Their compatibility with biodegradable PLA coatings - a feature that's becoming non-negotiable in European and North American markets.

Cost Analysis and ROI Projections

Purchasing a paper cup machine represents a significant investment ($50,000-$250,000), but operational economics reveal compelling returns:

- Power consumption: 5-8 kW/hour (equivalent to 3-5 household AC units)

- Labor needs: 1-2 operators per shift

- Material waste reduction: Advanced models achieve <3% scrap rates

A Midwest packaging company shared their ROI data: their Discover KSJ-120E machine paid for itself in 14 months by replacing outsourced cup production. The key was leveraging its rapid changeover capability (15-30 minutes between cup styles) to fulfill small-batch custom orders at premium margins.

Maintenance costs often surprise new operators. Budget 3-5% of machine value annually for:

- Daily: Cleaning and lubrication checks

- Monthly: Seal head inspections

- Quarterly: Drive system calibration

- Annually: Full electrical diagnostics

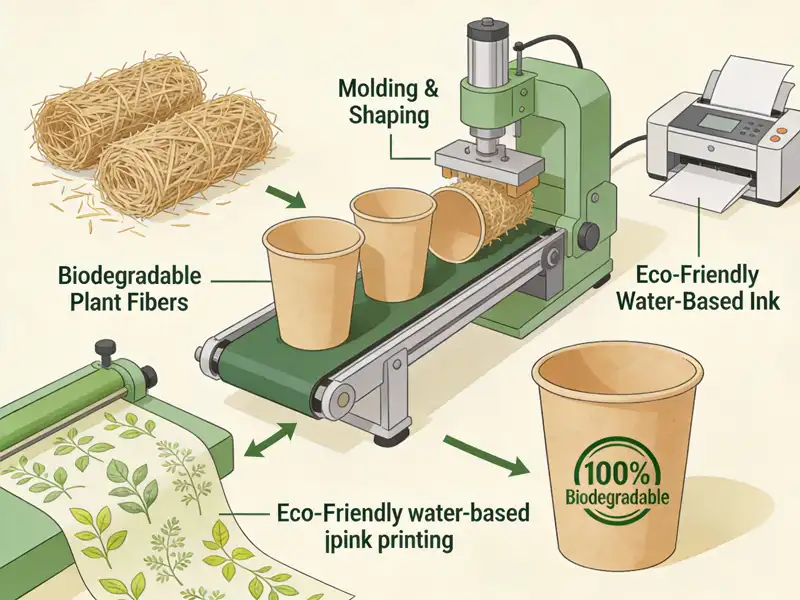

Sustainability and Material Compatibility

The paper cup machine industry faces increasing pressure to support eco-friendly production. Leading manufacturers now design equipment specifically for biodegradable materials:

- PLA (Polylactic Acid): Requires lower sealing temperatures (140-160°C vs 180-200°C for PE)

- PBAT coatings: Demands precise pressure control during base attachment

- Water-based barriers: Needs specialized drying tunnels

Discover Machinery's temperature-adjustable Leister heaters handle these variations seamlessly. During trials, their equipment maintained 98% seal integrity with PLA materials - matching conventional PE performance. The detection systems in premium models add another sustainability layer by rejecting defective cups before they waste materials.

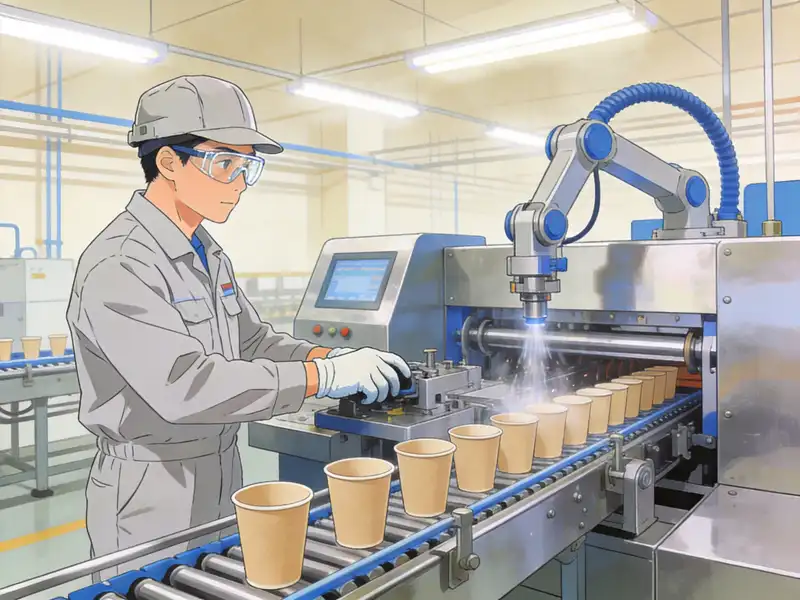

Operational Best Practices

Operating a paper cup machine efficiently requires more than pressing start buttons. Through consulting with multiple facilities, I've compiled these critical success factors:

- Material Handling: Store paper rolls vertically in climate-controlled areas (20-25°C, 40-60% RH) to prevent curling

- Tooling Management: Organize bottom punches and mandrels with RFID tags for instant changeover identification

- Quality Control: Implement hourly checks for:

- Base seal integrity (water test)

- Rim curl consistency (caliper measurement)

- Side seam strength (peel test)

The most overlooked aspect? Operator training. Facilities investing in 40+ hours of specialized instruction report 30% fewer downtime incidents. Discover Machinery sets the standard here with their comprehensive program covering everything from PLC diagnostics to biodegradable material handling.

Choosing Your Production Solution

Selecting the right paper cup machine requires honest assessment of three factors:

-

Volume Needs:

- <5 million cups/year: Medium-speed models (ZSJ series)

- 5-20 million: High-speed (KSJ series)

- 20+ million: Multiple KSJ units with automation integration

-

Product Diversity:

- Single cup type: Basic configuration

- 3+ sizes/styles: Advanced tooling package

- Biodegradables: Temperature-controlled sealing

-

Growth Strategy:

- Contract manufacturing: Prioritize changeover speed

- Private label: Focus on customization capabilities

- Sustainable branding: Require PLA/PBAT compatibility

Discover Machinery's equipment consistently delivers across these parameters. Their linear guide rail systems provide the stability needed for high-precision work, while the integral main cup shape mould ensures consistent quality even during 24/7 operations.

Ready to transform your packaging production? Explore Discover Machinery's paper cup machine lineup with detailed specifications and request a personalized ROI calculation. Visit their official equipment portal to schedule a virtual demo and discover how the right machinery can elevate your packaging business. For immediate consultation, contact their engineering team at +86-19817090303 or info@discoverxfx.com.