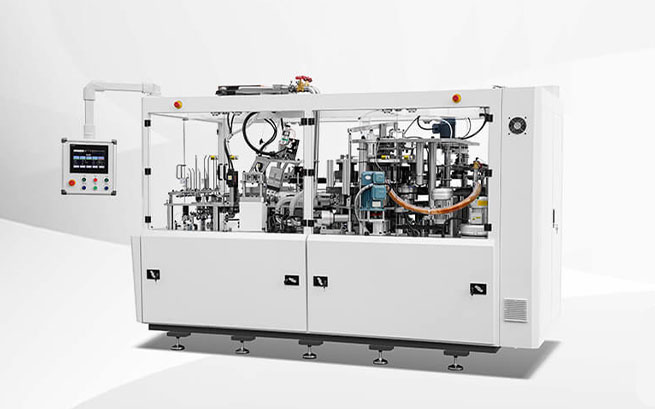

ZWJ-IV Intelligent Paper Bowl Machine is a machine use for production of paper bowls, like instant noodle bowls, soup bowls, salad bowls. It is a cutting-edge solution for high-speed, automated disposable bowl production. Engineered for precision, durability, and efficiency, it fits both large-scale factories and growing facilities. Driven by Double open type Cylindrical Cam, it ensures stable operation. The Uninterrupted integral spray lubrication system reduces wear for long life, while Swiss Leister air heater guarantees consistent bottom heating. Its integral machine base and linear guide paper conveyor boost smoothness, delivering reliable performance, lower labor costs, and consistent quality to optimize disposable bowl manufacturing.

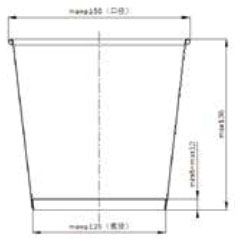

- Max. top diameter: 150mm

- Max. height: 136mm

- Production speed: 110-120pcs/min

- Air consumption: 0.6m³/min