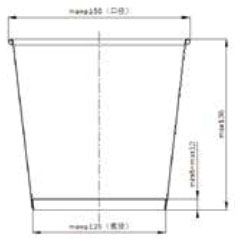

Cup mouth forming

After the bottom of the cup is formed, it is softened and lubricated at the oiling station to the cup mouth, and then the roll mouth station is turned, and after the cup mouth mold stamping on the pre-roll and re-roll positions, the final cup mouth is formed, and the quality of these parts directly affects the curling effect of the paper cup mouth, such as the flatness and tightness of the curling edge.

Paper feeding device

The paper feeding mechanism discharges the fan sheet on the paper supply holder through the suction cup, and the conveying mechanism then sends the fan sheet to the next position.

The bottom of the cup is formed

Through the web automatic feeding device and the circular punching mechanism, the bottom of the cup is punched and formed; After the bottom of the cup body is preheated and heated, the bottom of the cup is sealed with the cup body by the bottom rolling device.

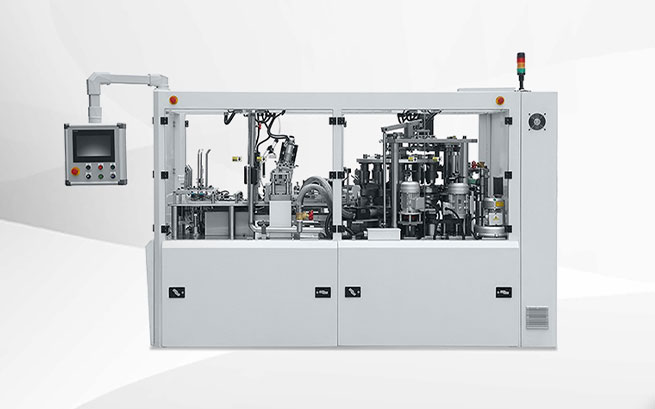

High-Speed and Fully Automated Production

The DWJ-IV integrates multiple processes, including paper feeding, sealing, heating, bottom punching, and curling. This seamless automation reduces manual labor, enhances production speed, and ensures uniform product quality.

Intelligent Control System

Equipped with a user-friendly touchscreen interface, the machine offers real-time monitoring and automated fault detection. Operators can quickly adjust settings for different bowl sizes, optimizing efficiency.

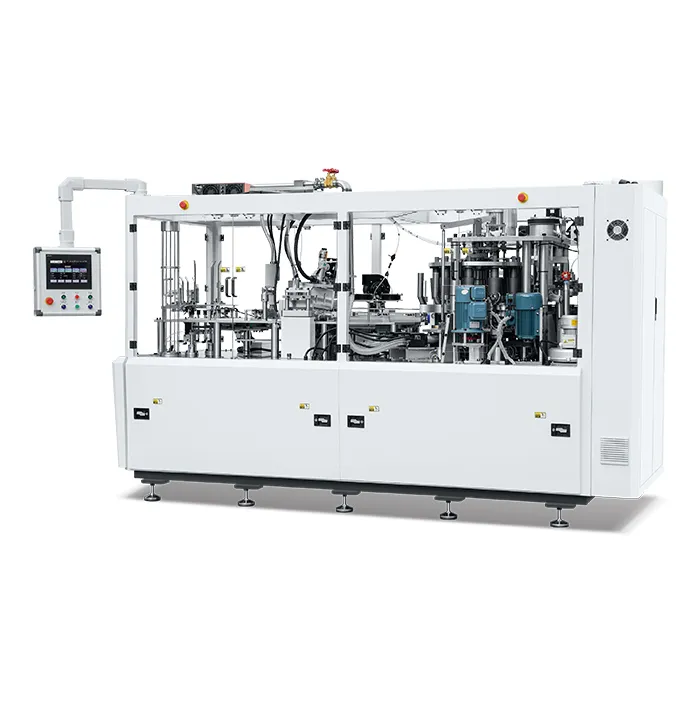

Versatile Manufacturing Capabilities

As a leading paper bowl maker machine, the DWJ-IV supports various paper materials, including PE-coated and biodegradable options. It accommodates multiple bowl sizes, making it ideal for diverse applications in food packaging, catering, and retail industries.

Robust and Durable Construction

Designed with a reinforced frame, this paper bowl machine products model minimizes vibrations and ensures long-term stability. Precision forming technology guarantees smooth, high-quality bowl edges, reducing waste and improving product consistency.

Energy-Efficient and Cost-Effective

The optimized heating system maintains precise temperature control while minimizing energy consumption. Its low-maintenance design reduces operational costs, making it a smart investment for businesses seeking long-term profitability.

Why Choose Discover Machinery's?

As a trusted provider of paper bowl making machine solutions, Discover Machinery's delivers high-performance equipment tailored to industry needs. The DWJ-IV combines automation, efficiency, and precision, ensuring businesses achieve maximum productivity with minimal waste.

For more details on our paper bowl machine products, contact Discover Machinery's today and upgrade your production capabilities!