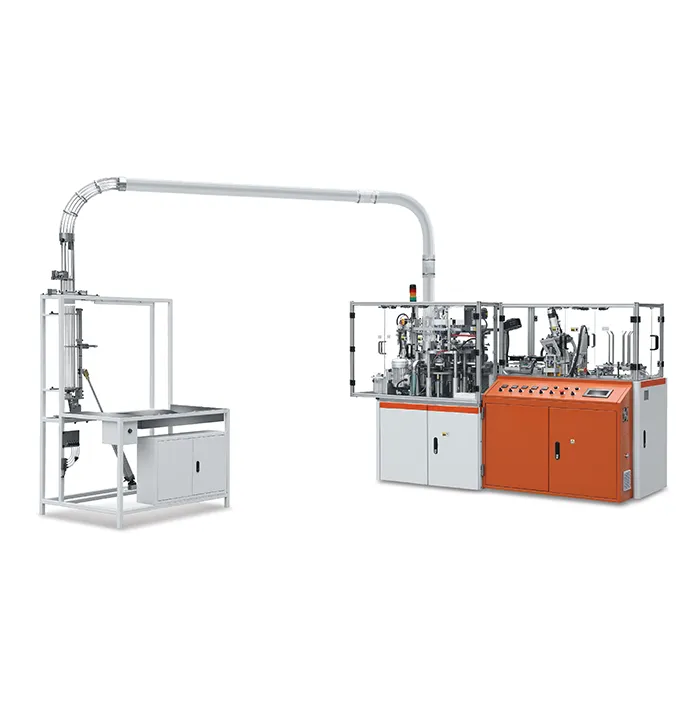

Fan-shaped piece feeding

The paper feeding mechanism discharges the fan-shaped sheet on the paper supply holder through the suction cup, and the conveying mechanism then sends the fan-shaped sheet to the next process.

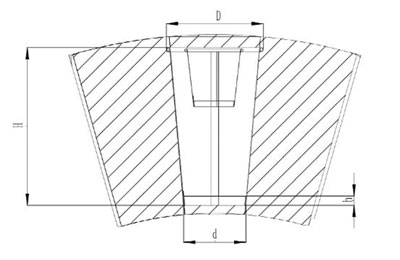

Crimping mold

It is used to curl the upper mouth of the paper cup. The shape and size of the crimping die need to match the mouth of the paper cup, and by applying pressure, the paper is rolled smoothly. The quality of these parts directly affects the curling effect of the mouth of the paper cup, such as the flatness and tightness of the curling.

Forming molds and heating elements

The forming mold is one of the key components of the paper cup machine, which determines the shape and size of the paper cup. The molds have high-precision shapes and sizes and are able to withstand high temperatures and pressures. The heating element heats the paper during the cup forming process, softening the paper for a better fit to the mold.

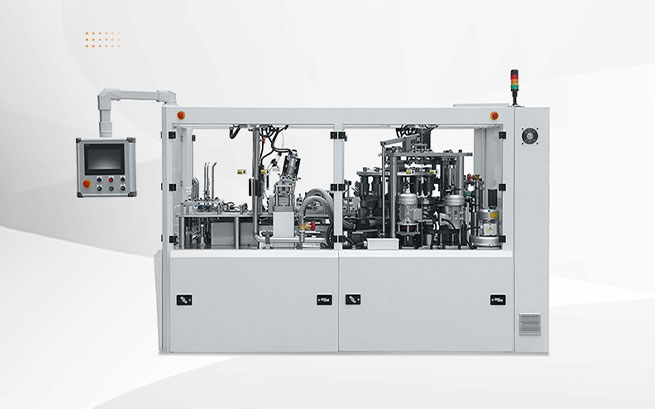

High-Speed and Stable Production

The KSJ-160 is engineered for high-speed output with consistent quality. Its efficient design ensures a smooth production process, making it an excellent investment for businesses looking for a small cost paper cup making machine that delivers reliable results.

Cost-Effective Solution for Businesses

Designed with affordability in mind, this machine provides high-quality production at a competitive price. It is ideal for manufacturers aiming to reduce costs without compromising on efficiency. As a leading paper cup machine manufacturer, we ensure that our machines offer the best value in the industry.

Fully Automated for Seamless Operation

The KSJ-160 automates the entire cup production process, from paper feeding and bottom sealing to curling and cup stacking. This advanced automation reduces manual labor, improves efficiency, and enhances overall production output.

Leak-Proof and Strong Sealing Technology

Equipped with cutting-edge ultrasonic and heat-sealing technology, the machine guarantees secure sealing, preventing leaks and ensuring the durability of every cup. It is designed to handle both single and double PE-coated paper, making it suitable for a variety of tea cup applications.

Versatile and Compatible with Different Paper Materials

This machine is adaptable to various paper materials, allowing manufacturers to produce cups suitable for tea, coffee, and other beverages. The ability to work with multiple coatings ensures flexibility in production.

Intelligent Control System

A user-friendly touchscreen interface allows for easy monitoring and adjustment of production settings. This intelligent system enhances accuracy and reduces downtime, making operations more efficient.

Energy-Efficient and Eco-Friendly Design

As a small cost paper cup making machine, the KSJ-160 is designed to consume minimal power while maximizing performance. Its energy-efficient features help manufacturers reduce operational costs and contribute to sustainable production.

Durable Construction for Long-Term Use

Built with high-quality materials, this machine ensures stability and longevity. Its reinforced structure reduces vibrations, enhancing precision and extending the machine's lifespan.

Low Maintenance and Easy Operation

Designed for user convenience, the KSJ-160 requires minimal maintenance. Easily accessible components allow for quick servicing, ensuring continuous and smooth production.

Reliable Support from a Leading Paper Cup Machine Manufacturer

At Discover Machinery's, we pride ourselves on providing top-quality machines backed by expert customer support. As a trusted paper cup machine manufacturer, we offer reliable after-sales service, technical assistance, and spare parts to ensure long-term efficiency for our clients.

Why Choose Discover Machinery's?

As one of the most experienced automatic paper cup making machine manufacturers, Discover Machinery's is dedicated to delivering advanced, cost-effective, and high-speed solutions for the paper cup industry. The KSJ-160 Paper Tea Cup Making Machine is an ideal choice for businesses seeking a small cost paper cup making machine that guarantees precision, efficiency, and durability. For more information on how our paper cup machine manufacturer expertise can enhance your production capabilities, contact Discover Machinery's today. Let us help you take your paper cup manufacturing to the next level.