Control system

Operators can set various parameters such as production speed, temperature, pressure, etc. through the control panel. The control system can also monitor the running status of the machine in real time, and in case of failure, it can send out an alarm and display fault information in time, which is convenient for maintenance personnel to troubleshoot.

Crimping mold

It is used to curl the upper mouth of the paper cup. The shape and size of the crimping die need to match the mouth of the paper cup, and by applying pressure, the paper is rolled smoothly. The quality of these parts directly affects the curling effect of the mouth of the paper cup, such as the flatness and tightness of the curling.

Fan-shaped piece feeding

The paper feeding mechanism discharges the fan-shaped sheet on the paper supply holder through the suction cup, and the conveying mechanism then sends the fan-shaped sheet to the next process.

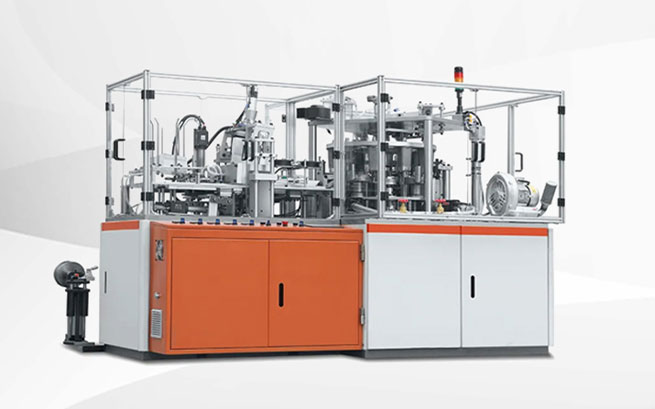

Advanced Automation for High-Speed Production

The FBJ-L is a fully automatic paper bowl machine equipped with a high-speed servo system that enhances production efficiency while ensuring precise and stable operation. From paper feeding and heating to forming, sealing, and edge curling, every step is automated to minimize manual intervention and reduce labor costs. This advanced automation not only boosts output but also guarantees consistency in every batch, making it a highly efficient solution for businesses looking to scale their operations.

Durable and Reliable Structural Design

Built for long-term durability, the FBJ-L paper bowl making machine features a reinforced mechanical frame that reduces operational vibrations and noise. High-quality components and an automatic lubrication system extend the machine’s lifespan while minimizing maintenance requirements. The precision-driven cutting and sealing mechanisms ensure smooth and secure bowl edges, preventing defects and enhancing overall product quality.

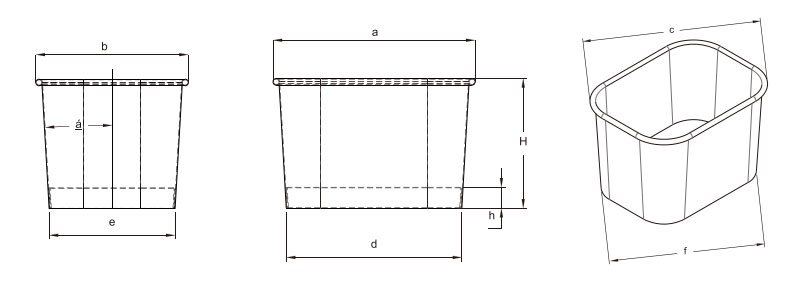

Versatile Production Capabilities

As a trusted paper bowl machine manufacturer, Discover Machinery's understands the need for flexibility in production. The FBJ-L supports various bowl sizes and designs, making it suitable for a wide range of applications, from small snack bowls to large meal containers. The machine is compatible with different paper materials, including single and double PE-coated paper, as well as biodegradable options, catering to the growing demand for eco-friendly packaging solutions.

Intelligent Control System for Seamless Operation

The FBJ-L fully automatic paper bowl machine is designed with a smart touchscreen interface, offering an intuitive and user-friendly experience. Real-time production monitoring, automated fault detection, and instant error alerts allow operators to manage production with ease. The intelligent system ensures smooth adjustments and quick transitions between different bowl sizes, improving overall efficiency and reducing downtime.

Energy-Efficient and Cost-Effective Performance

Efficiency is a key feature of the FBJ-L paper bowl making machine, designed to optimize energy consumption without compromising speed or quality. Its advanced heating system ensures precise temperature control, reducing energy waste while maintaining consistent forming and sealing quality. This not only lowers operational costs but also supports sustainable and eco-friendly manufacturing practices.

Enhanced Safety Features for Secure Operation

To ensure safe and reliable operation, the FBJ-L fully automatic paper bowl machine is equipped with multiple safety mechanisms. An enclosed production area minimizes exposure to moving parts, while an intelligent fault detection system automatically stops operations in case of abnormalities. These safety features comply with international industry standards, providing a secure working environment for operators.

Why Choose Discover Machinery's?

As a professional paper bowl machine manufacturer, Discover Machinery's is dedicated to providing high-quality solutions that combine innovation, efficiency, and durability. The FBJ-L Intelligent paper bowl making machine is a testament to our commitment to precision engineering and customer satisfaction. With advanced technology and reliable performance, this machine is the perfect choice for businesses looking to enhance their production capabilities.

For more information or to discuss customization options, contact Discover Machinery's today. Upgrade your manufacturing process with our industry-leading fully automatic paper bowl machine and achieve new levels of efficiency in paper bowl production.