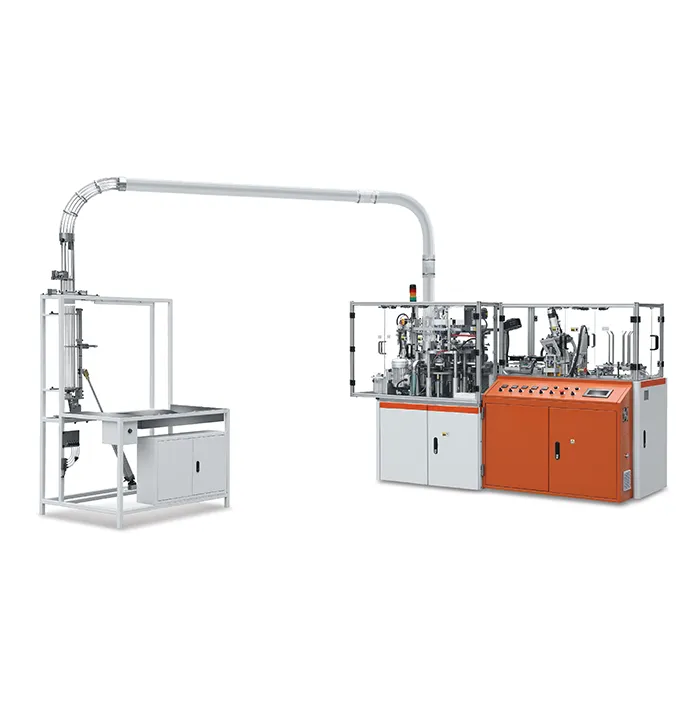

Paper feeding device

The paper feeding mechanism discharges the fan sheet on the paper supply holder through the suction cup, and the conveying mechanism then sends the fan sheet to the next position.

Cup body forming

After the fan-shaped piece reaches the designated position, through the leaf holding mechanism, the reciprocating motion of the holding hand is driven, and the fan-shaped piece is hugged around the mold, and the paper cup body is formed.After molding, the ultrasonic briquetting above the leaf holding mechanism moves down to compress the longitudinal seam, and the ultrasonic vibration heats up to melt the surface of the paper stacking part, and the longitudinal seam can be sealed after cooling

The bottom of the cup is formed

Through the web automatic feeding device and the circular punching mechanism, the bottom of the cup is punched and formed; After the bottom of the cup body is preheated and heated, the bottom of the cup is sealed with the cup body by the bottom rolling device

Cup mouth forming

After the bottom of the cup is formed, it is softened and lubricated at the oiling station to the cup mouth, and then the roll mouth station is turned, and after the cup mouth mold stamping on the pre-roll and re-roll positions, the final cup mouth is formed, and the quality of these parts directly affects the curling effect of the paper cup mouth, such as the flatness and tightness of the curling edge.

Fully Automatic Operation

The machine automates the entire process, from paper feeding to cup forming, sealing, and bottom curling, significantly reducing manual labor while enhancing production efficiency.

High-Speed Performance

Designed for medium to high-speed production, this fully automatic paper cup making machine can manufacture a large number of 7oz cups per hour, ensuring a steady supply for commercial use.

Precision Engineering

Equipped with servo control technology, the machine ensures accurate cup forming, reducing material waste and maintaining consistency in size and shape.

Durable and Reliable Design

The machine's robust construction with high-quality components ensures long-lasting performance with minimal maintenance.

Versatile Application

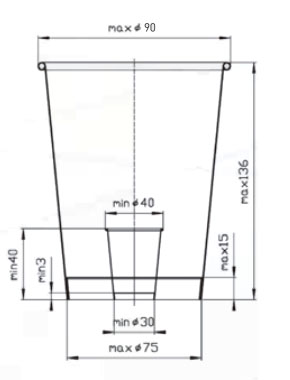

Suitable for producing a wide range of disposable cups, it supports various paper materials, including single and double PE-coated paper, meeting diverse industry demands.

Intelligent Fault Detection

The machine is integrated with an advanced monitoring system that detects and alerts operators about any operational issues, ensuring smooth production with minimal downtime.

Energy Efficiency

Optimized for low power consumption, this disposable paper cup making machine offers cost savings while maintaining high production efficiency.

Competitive Paper Plate Cup Making Machine Price

At Discover Machinery's, we understand the importance of cost-effectiveness in manufacturing. That’s why we offer competitive paper plate cup making machine price options without compromising on quality. Our Intelligent ZSJ-Ⅲ is designed to provide an excellent return on investment, ensuring businesses benefit from both high efficiency and affordability.

Why Choose Discover Machinery's?

With years of expertise in the industry, Discover Machinery's is committed to providing professional, high-quality solutions for paper cup manufacturing. Our fully automatic paper cup making machine is engineered to meet the highest industry standards, delivering precision, durability, and reliability. We provide comprehensive after-sales support, including installation guidance, technical assistance, and spare parts supply, ensuring uninterrupted operation for our clients. For businesses looking for a premium disposable paper cup making machine, the Intelligent ZSJ-III offers the perfect balance of performance, cost, and innovation. Contact us today to learn more about our paper plate cup making machine price and how our solutions can enhance your production capabilities.