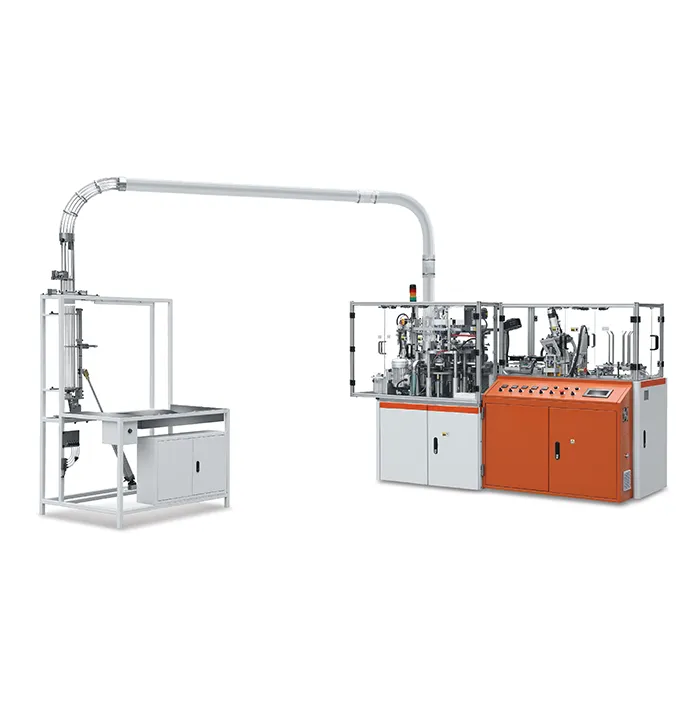

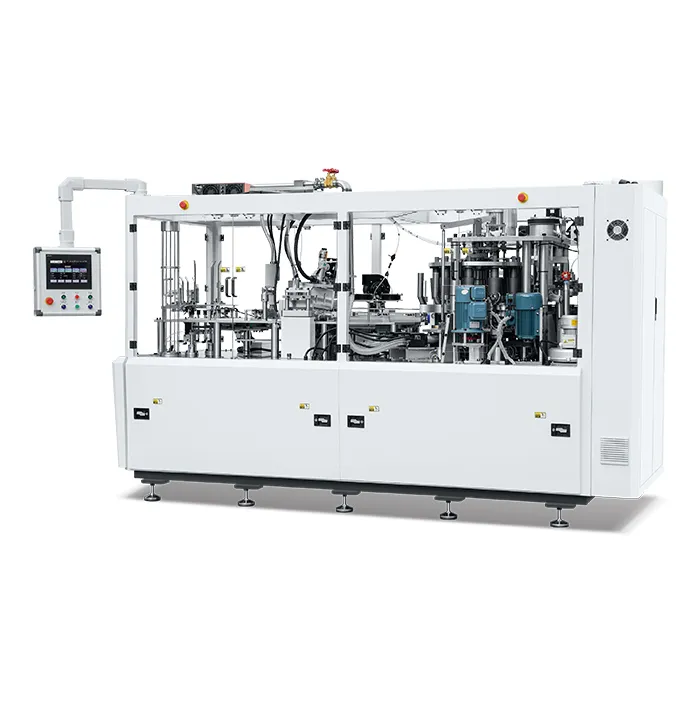

The Discover High-Speed Paper Cup Making Machine is the pinnacle of efficiency and reliability in disposable cup manufacturing. Engineered for maximum output with minimal downtime, this fully automated system seamlessly produces a wide range of paper cup sizes with impeccable precision. Incorporating advanced PLC control systems and robust crimping technology, Discover machinery guarantees superior cup quality, reduced material waste, and a rapid return on investment. For businesses aiming to scale production, reduce operational costs, and dominate the competitive packaging market, the Discover paper cup machine is the definitive solution.

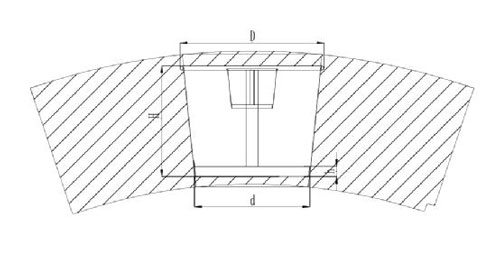

- Cup sizes: 5-24 oz

- Productlon speed: 80-90pcs/min

- Paper grams: 210-350gsm

- Air consumption: 0.4m³/min