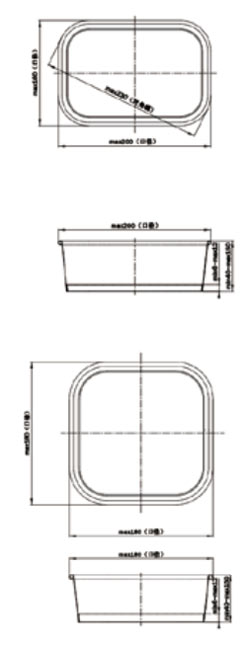

What is the maximum size range of rectangular paper buckets this machine can produce?

The intelligent rectangular paper bucket machine supports a maximum top diameter of 230mm and height adjustments from 40mm to 150mm, making it suitable for both small containers and large industrial buckets. Custom mold options are available for specific size requirements—contact us to discuss your exact needs.

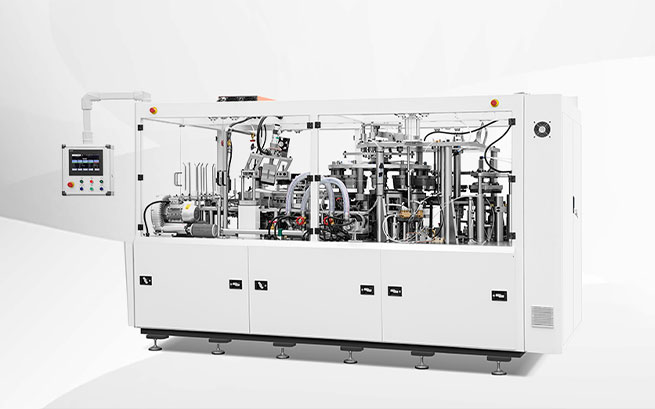

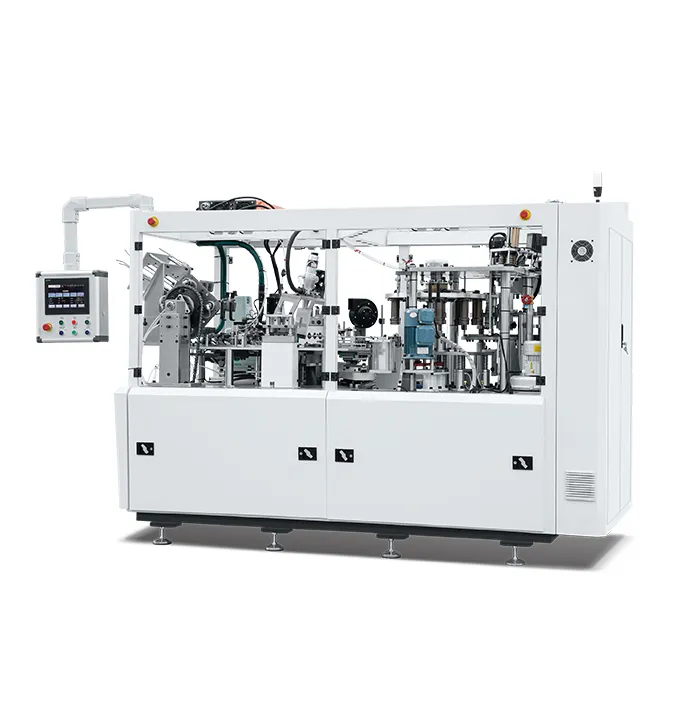

What production speed does the FTJ-IV intelligent rectangular paper bucket machine achieve?

This machine operates at a high-speed production rate of 55–65 pieces per minute, balancing efficiency with precision. The double open cylindrical cam drive system ensures consistent output even during long production runs. For detailed capacity projections based on your target volume, request our production calculator tool.

Which materials can be used with this rectangular paper bucket machine?

The machine is compatible with single/double PE-coated paper for moisture resistance and biodegradable paper for eco-friendly packaging. It handles paper weights suitable for food-grade and industrial applications. Our technical team can help optimize material selection for your specific product—reach out for material compatibility testing.

What makes the 4-corner synchronized forming technology unique?

The patented 4-corner forming system uses independent servo controls to ensure uniform pressure distribution across all corners, eliminating weak points common in traditional forming methods. This results in structurally stable buckets with consistent wall thickness. See the technology in action with our live demo videos.

How does the machine ensure leak-proof sealing for food packaging applications?

Equipped with a Swiss Leister air heater and precision temperature control, the machine delivers uniform heat distribution for secure, leak-proof seams. It also includes an automated inspection system that performs pressure decay tests (0.35 bar for 30 seconds) on random samples. Ask about our food-grade certification documentation.

What is the PLC control system capable of monitoring and adjusting?

The advanced PLC system provides real-time production monitoring, including speed, temperature, and defect rates. Its user-friendly touchscreen allows operators to adjust parameters like forming pressure and heating profiles, while built-in diagnostics minimize downtime. Training on the control system is included with purchase.

How long does it take to change molds for different bucket sizes?

With the quick-change mold system and QR code parameter loading, complete mold changes take under 30 minutes. Each mold set stores preset parameters (pressure, temperature, timing) that auto-load when scanned, reducing setup errors. We offer mold customization services for unique bucket designs.

What are the power and air consumption requirements for operation?

The machine requires a 380V power supply with a rated power of 36KW and air consumption of 0.8m³/min. Our energy-efficient design includes variable speed drives and heat recovery systems to lower operational costs. Request a detailed energy consumption analysis for your production scenario.

What after-sales support is included with the intelligent rectangular paper bucket machine?

We provide a 12-month warranty, on-site installation training, and 24/7 technical support. Our spare parts warehouse stocks common components for quick delivery, and we offer preventive maintenance programs. Extended warranty options are available—ask our sales team for details.

Can the machine produce square buckets in addition to rectangular ones?

Yes, the FTJ-IV supports both rectangular and square bucket production with mold changes. The forming system adapts to different corner radii, making it versatile for various packaging needs. Share your desired bucket dimensions for a custom mold quote.

How does this machine contribute to sustainable packaging production?

By using biodegradable paper materials and optimizing material usage (minimizing waste through precision cutting), the machine supports eco-friendly packaging initiatives. Its energy-efficient components also reduce carbon footprint. We can help calculate your sustainability metrics when switching from plastic packaging.

What quality control features are integrated into the production process?

The machine includes an automated inspection system that checks for dimensional accuracy, seal integrity, and surface defects. Rejected products are automatically diverted, ensuring only合格 buckets reach the output conveyor. Statistical process control reports are available for quality audits.

What is the typical return on investment for this paper bucket machine?

ROI depends on production volume, but most clients see payback within 12–18 months. Key factors include labor savings (fully automated operation), material efficiency (5% waste reduction), and high output rates. Contact us for a customized ROI calculator based on your production goals.

Are there optional accessories to enhance production capabilities?

Optional equipment includes a Paper Blank Feeder for continuous material supply and an advanced Inspection System with vision cameras for detailed defect analysis. These upgrades can increase throughput by up to 15%. Ask about bundle pricing for complete production line solutions.

How does the machine handle thick or coated paper materials without jamming?

The linear guide paper feeding system uses adjustable tension controls to handle thick PE-coated papers smoothly. The Swiss Leister heater ensures proper material softening, preventing cracks during forming. Our technical manual includes material specifications and setup guides for optimal performance.