What is the production capacity of the Automatic Paper Bucket Forming Machine?

The machine operates at a speed of 35–45 pieces per minute, making it ideal for medium-scale production needs. This output balances efficiency with precision, ensuring consistent quality even during extended runs. For businesses like KFC China, which uses our 10L bucket solution, this speed translates to reliable supply for high-demand food packaging operations.

What sizes of paper buckets can this machine produce?

It supports a wide range of dimensions: top diameters from φ160mm to 225mm and heights from 40mm to 1210mm. This versatility allows production of buckets from small snack containers to large 10L industrial storage buckets, meeting diverse needs across food packaging and industrial sectors.

What materials are compatible with the medium speed paper bucket forming machine?

The machine works with 210–320gsm paper with PE coating (single or double-sided) and biodegradable paper options. The PE coating ensures leak resistance for food applications, while biodegradable materials support eco-friendly packaging initiatives—critical for brands prioritizing sustainability.

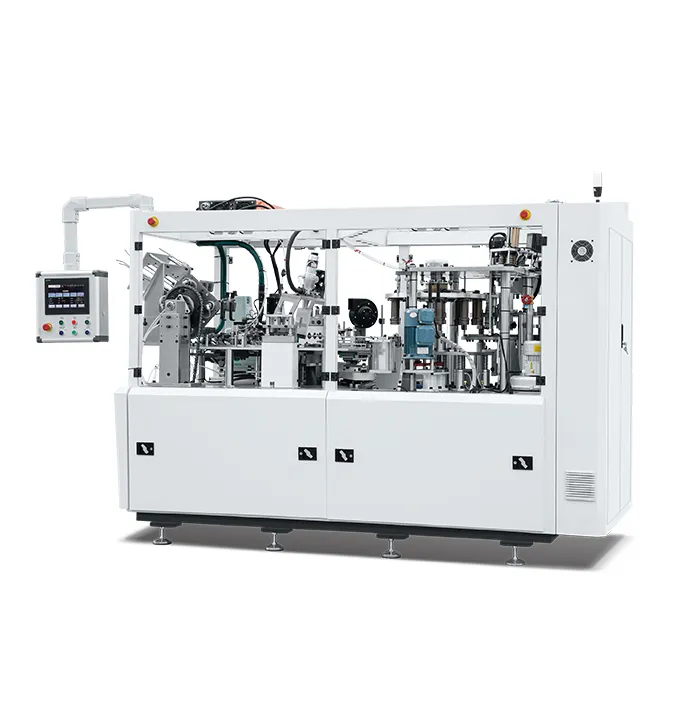

What technical features make this Automatic Paper Bucket Forming Machine stand out?

Key advantages include a PLC control system for precise automation, Leister bottom heater for consistent sealing, gear transmission for stable operation, automatic lubrication to reduce maintenance, and a three-holed robot arm for efficient stacking. These components ensure high-quality output with minimal downtime.

How does the machine ensure product quality and leak resistance?

The combination of precision forming molds, Leister heaters, and PLC-controlled sealing processes guarantees strong, leak-proof seams. For food packaging clients like KFC, this means reliable containment of liquids and oils, while industrial users benefit from sturdy buckets for storage and transport.

What are the power and air requirements for operation?

The machine operates on 4x380V 50Hz power supply with a rated power of 18KW, and requires an air consumption of 0.4m³/min. These specifications are standard for industrial equipment, ensuring easy integration into most manufacturing setups.

What optional equipment is available for the Automatic Paper Bucket Forming Machine?

Optional add-ons include an Inspection System for quality control and a Paper Blank Feeder to enhance automation. These upgrades help reduce manual labor and improve production consistency—ideal for businesses looking to scale operations.

What after-sales support is provided with the automatic paper bucket forming machine?

We offer a 12-month warranty from installation, plus on-site installation training, technical support, and a guaranteed supply of spare parts. Our team provides comprehensive training to ensure your staff can operate and maintain the machine efficiently, minimizing disruptions.

How easy is it to maintain the medium speed paper bucket forming machine?

The automatic lubrication system and durable gear transmission reduce maintenance needs. Routine upkeep involves basic cleaning and periodic checks of wear parts, which are readily available from our stock. This design ensures long-term reliability with minimal downtime.

Can the machine handle custom bucket designs or branding?

Yes, the forming molds can be customized to accommodate specific bucket shapes, and the machine works with printed PE-coated paper for branded packaging. This flexibility is popular with food chains and retail brands looking to enhance product visibility.

What is the typical price range for an Automatic Paper Bucket Forming Machine?

Pricing varies based on configuration (e.g., optional Inspection System or Paper Blank Feeder). For a detailed quote tailored to your production needs, contact our sales team—we offer competitive rates with transparent breakdowns to help you calculate ROI effectively.

Is the machine suitable for small to medium-sized businesses?

Absolutely. With its medium-speed output (35–45pcs/min) and scalable options, it’s designed to grow with your business. Whether you’re a startup in food packaging or an established industrial supplier, the machine balances performance and affordability.

How long does installation and training take?

Our technical team provides on-site installation, typically completed within 3–5 days, followed by 2–3 days of hands-on training. This ensures your team is fully proficient in operation and maintenance before we hand over the machine.

What makes this machine suitable for KFC-level food packaging standards?

Its ability to produce 10L large-capacity buckets with consistent quality aligns with the demands of major food chains. The Leister heating system ensures secure sealing, while the PLC control maintains uniformity—critical for brands prioritizing safety and presentation.

How can I inquire about the paper bucket machine price or request a demo?

For pricing details, custom solutions, or to schedule a virtual demo, reach out to our sales team via the contact form on our website. We’ll provide personalized support to help you determine if this Automatic Paper Bucket Forming Machine fits your production goals.