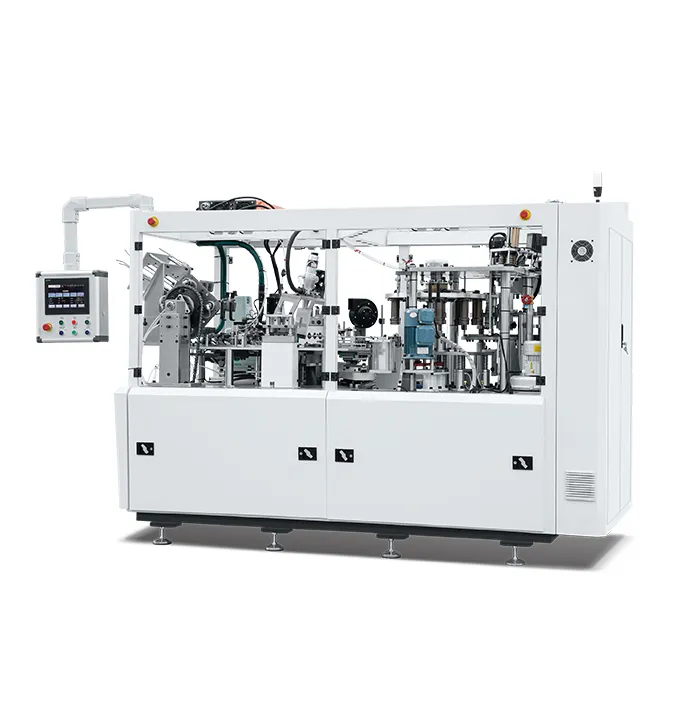

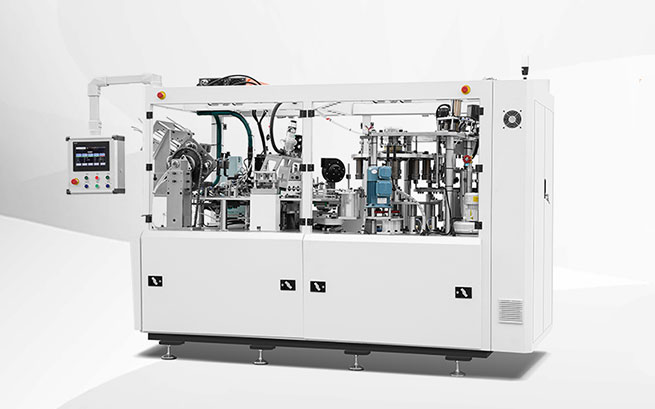

WBJ-IV Intelligent Outer Wrap Machined is a machine mainly used for the production of double wall cups with inner cup diameter less than 110mm, and can Iproduce various special cups like paper outer wrapped plastic cup by changing some parts.

- Paper bowl size: 4-20 oz

- Paper gram weight: 190-300gsm

- Production speed: 120-140pcs/min

- Paper type: single PE or double PE