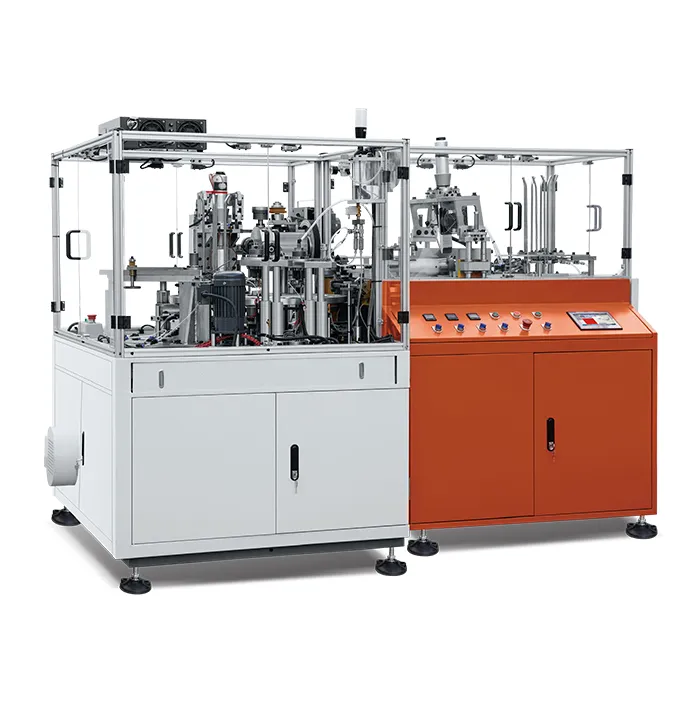

1.High-Speed and Efficient Production – Capable of producing a large number of double-walled paper cups per hour with precise bonding and seamless operation.

2.Advanced Automation – Equipped with PLC control, servo motor precision, and automatic error detection for smooth and intelligent production.

3.Durable and Reliable – Built with high-quality materials and designed for long-term, stable operation in high-demand environments.

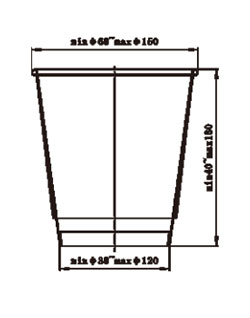

4.Versatile and Customizable – Supports various cup sizes and designs, allowing businesses to meet diverse customer needs.

5.Energy-Efficient and Eco-Friendly – Optimized power consumption and compatibility with biodegradable materials support sustainable production.

6.Comprehensive Safety Features – Enhanced safety mechanisms and user-friendly maintenance features ensure a secure and hassle-free operation.