Introduction

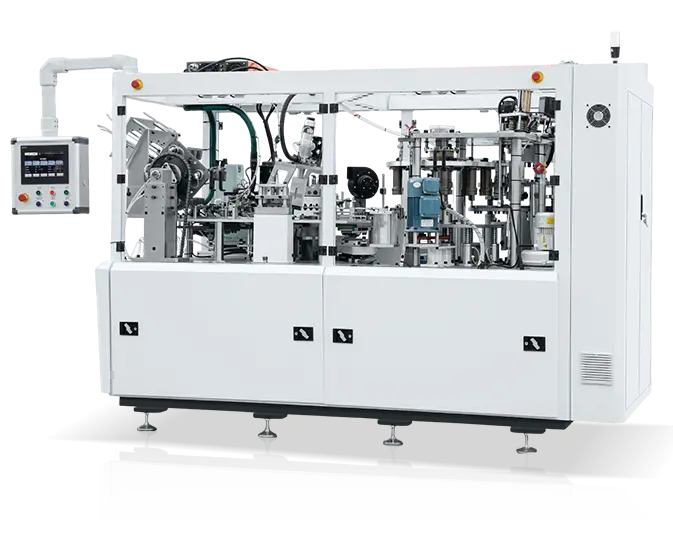

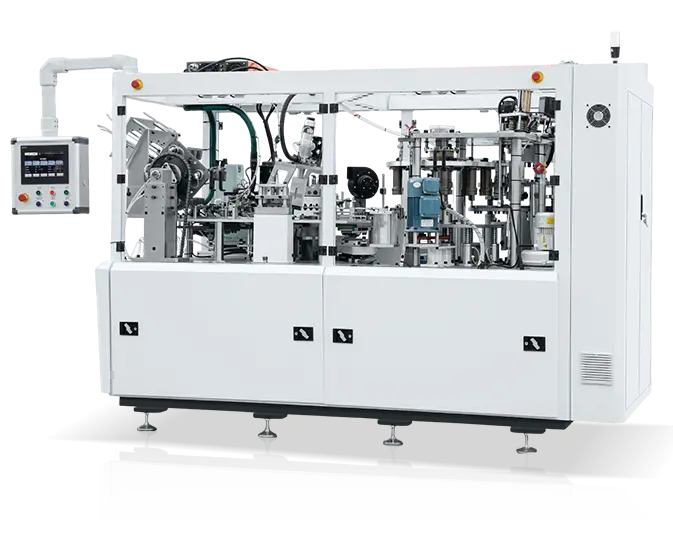

The paper cup manufacturing industry has witnessed significant growth in recent years, driven by the increasing demand for disposable cups in the food and beverage sectors. However, like any machinery, paper cup machines can encounter various malfunctions that affect the quality of the end - products and production efficiency. This article aims to delve into common paper cup machine faults, their causes, and practical solutions, providing valuable insights for manufacturers and operators.

1. Poor Paper Cup Molding

One of the most prevalent issues is poor paper cup molding, which manifests as cup body deformation, uneven bottoms, and non - round cup mouths.

The primary culprits behind this problem include worn - out molds. Over time, continuous use can cause the molds to lose their precision, leading to inconsistent cup shapes. Additionally, unsmooth paper feeding (unsmooth paper feeding) can disrupt the cup - forming process. If the paper does not move through the machine evenly, it may result in misaligned cup components. Insufficient hot - pressing temperature also plays a part. Inadequate heat fails to properly bond the paper layers, causing the cup to lack structural integrity. Pressure imbalance can further exacerbate the issue, as uneven pressure during the molding process can lead to distorted cup shapes.

To address these problems, it is essential to regularly check and adjust the mold clearance. This ensures that the mold can accurately shape the paper into cups. Ensuring smooth paper feeding is also crucial. This may involve inspecting the paper feeding mechanism for any blockages or misalignments. Adjusting the hot - pressing temperature and time according to the paper type and cup specifications is necessary to achieve optimal bonding.

2. Poor Sealing Quality (Leakage)

Paper cups with poor sealing quality, leading to leakage, are a major concern for manufacturers. The root causes of this problem are diverse. Incorrect heat - sealing temperature can be a significant factor. If the temperature is too low, the adhesive may not melt properly, resulting in weak seals. Conversely, excessive heat can damage the paper and the adhesive, also causing leakage. Insufficient pressure during the sealing process fails to ensure a tight bond between the cup layers. Contaminated molds can prevent proper adhesion, as dirt or debris on the mold surface can interfere with the sealing process. Moreover, the use of low - quality glue is a common cause of poor sealing.

To resolve these issues, it is necessary to calibrate the heat - sealing temperature accurately. This requires regular temperature checks and adjustments based on the type of paper and adhesive used. Adjusting the pressure to an appropriate level is also vital. Cleaning the molds thoroughly at regular intervals helps to maintain a clean surface for proper adhesion. Using adhesives that meet the required specifications is fundamental to ensuring reliable seals.

3. Inconsistent Paper Cup Sizes

Inconsistent paper cup sizes can occur due to several reasons. Incorrect equipment settings are often the first suspect. If the machine is not calibrated correctly, it may produce cups of varying sizes. Fluctuations in raw material specifications can also contribute to this problem. If the paper thickness or width varies from batch to batch, it will affect the cup size. Additionally, misaligned mold positioning can lead to inconsistent cup dimensions.

To combat this issue, regular equipment calibration is essential. This ensures that the machine is set to produce cups of the desired size. Monitoring the consistency of raw materials is also crucial. By closely inspecting incoming paper batches, manufacturers can identify and address any issues with raw material quality. Checking and realigning the mold installation helps to maintain accurate cup dimensions.

4. Frequent Paper Jams (Paper - Feeding Malfunctions)

Frequent paper jams can significantly disrupt the production process. Clogged paper paths are a common cause. Any debris, such as paper scraps or dust, can accumulate in the paper - feeding mechanism, blocking the paper's movement. Uneven paper thickness can also cause problems, as it may cause the paper to jam when passing through the rollers. Worn - out paper - feeding rollers can fail to grip the paper properly, resulting in jams.

To solve these problems, it is necessary to clean the paper path regularly. This involves removing any debris or blockages that may have accumulated. Using paper with consistent thickness is advisable. Checking and repairing the paper - feeding rollers, or replacing them if necessary, ensures proper paper feeding.

5. Abnormal Noise and Vibration

Abnormal noise and vibration in paper cup machines can indicate underlying problems. Loose components are often the cause. Over time, the constant operation of the machine can cause bolts and nuts to become loose, resulting in vibrations. Worn - out bearings can also lead to noise and vibration, as they are unable to support the smooth rotation of machine parts. Insufficient lubrication can exacerbate the problem, as it increases friction between moving parts. An unsteady machine installation can also contribute to abnormal vibrations.

To address these issues, it is important to regularly check and tighten any loose components. Replacing worn - out bearings in a timely manner is crucial. Ensuring adequate lubrication of all moving parts helps to reduce friction and noise. Finally, ensuring that the machine is installed on a flat and stable surface is essential for minimizing vibrations.

Conclusion

Proper troubleshooting and maintenance of paper cup machines are vital for ensuring high - quality production and efficient operation. By understanding the common faults, their causes, and implementing the appropriate solutions, manufacturers can minimize downtime, improve product quality, and enhance their competitiveness in the market. Regular inspections, timely repairs, and proper calibration of the equipment are the keys to a smoothly running paper cup manufacturing process.