If you're searching for "smart paper cup forming machines," you're likely under immense pressure. You need a solution that addresses all your challenges. The answer isn't just a new machine; it's a strategic shift. The emerging trend is clear: sustainable packaging, powered by intelligent automation, is no longer a niche—it's a necessity. At the heart of this shift is the advanced Paper Bucket Machine. This isn't your grandparents' forming equipment. We're talking about smart, connected systems that transform rolls of recycled paperboard into sturdy, branded containers with startling efficiency. This article unpacks everything: the "why" behind the trend, the "how" of the technology, and the real-world impact a Discover Intelligent Paper Bucket Machine can have on your bottom line and brand reputation. We'll move past the hype and into the practical, operational gains you can expect.

Why Your Packaging Production Line Desperately Needs an Upgrade

Walk onto any production floor still reliant on manual forming or older plastic machinery, and you can almost hear it: the quiet groan of inefficiency. The story is familiar. Skilled labor is hard to find and harder to retain for repetitive tasks. Consistency wobbles—one batch of containers is perfect, the next has weak seams. The pile of off-spec waste in the corner grows daily. Meanwhile, the market has pivoted beneath your feet. Major retailers and conscious consumers now view single-use plastics with a hard eye. Legislation is tightening. Your sales team is coming back with requests you can't fulfill: "Can we get a compostable option?" "Our new client wants a paper bucket for their premium product."

This is the precise pain point the modern Paper Bucklet Forming Equipment addresses. It’s a direct response to a commercial and ethical imperative. Data from the Paperboard Packaging Council shows a sustained double-digit annual growth in demand for paper-based foodservice packaging. It’s not a fad; it’s a fundamental realignment. The machine you’re considering isn't just a capital expenditure; it's a bridge to the future market. It answers the buyer’s need for a sustainable packaging solution that doesn’t sacrifice performance. Think of the paper bucket—it’s microwave-safe, freezer-ready, oil-resistant with proper lining, and boasts a premium feel that plastic struggles to match. It’s a tangible signal to your end-consumer that your brand is part of the solution.

Unveiling the "Intelligence" in Smart Forming Technology

So, what separates a smart paper bucket forming machine from a simple mechanical die-cutter? The difference is in the brain, not just the brawn. Let’s demystify the tech without the jargon.

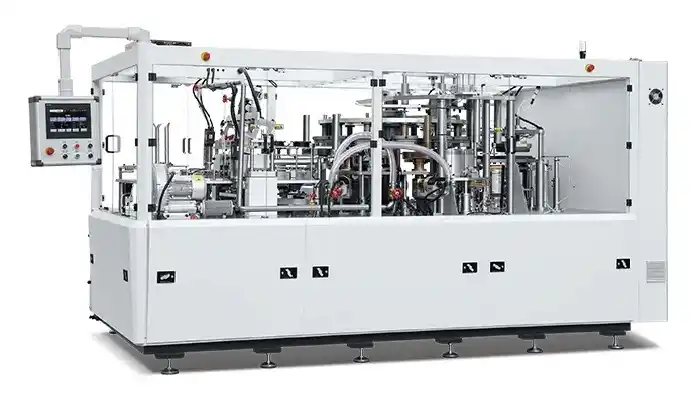

First, the core magic is precision engineering. A Discover machine doesn't just press paper; it coaxes it. Using a combination of precise heat, pressure, and servo-driven motion, it forms consistent, leak-resistant sidewalls and a perfectly locked bottom seam every single time. This mechanical heart is non-negotiable for durability.

But "intelligent" refers to the layer of digital oversight. Imagine sensors that monitor the tension of the paper web feed. Too tight, and it risks tearing; too loose, and the alignment slips. The machine adjusts in microseconds. Consider thermal sensors ensuring the heating plates are at the exact optimal temperature for your specific material grade—too cool and the adhesive doesn't set; too hot and you scorch the board. This is real-time process control, eliminating variables that human operators simply cannot catch.

Then comes connectivity. A true Intelligent Paper Bucket Machine offers a simple HMI (Human-Machine Interface) touchscreen. Here, your operator selects the job: "2-liter premium ice cream bucket, branded print." The machine recalls all parameters: tooling position, heat settings, speed. It’s like a playlist for production. This drastically reduces changeover time from hours to minutes, slashing downtime. It also collects data—OEE (Overall Equipment Effectiveness), production counts, error logs. This isn't just data for data's sake; it's the blueprint for predictive maintenance. The machine might alert you that a bearing is showing a slight friction increase, suggesting service next week, rather than failing catastrophically tomorrow. This intelligence transforms your operation from reactive to proactive.

How Discover Customizes Machines to Your Specific Needs

Any supplier can sell you a standard machine. The challenge is making that machine thrive in your factory, with your materials, for your unique products. This is where the partnership with Discover diverges from a simple transaction. We start with a conversation about your "before" picture.

Picture this: You primarily produce containers for dry goods but have a new contract for a wet salad line. The lining requirements are different. The seam integrity needs to be bulletproof. A generic machine might struggle. Our team of engineers will delve into the specifics of your barrier materials—the PLA linings, the PE coatings—and calibrate the thermal forming and sealing modules to match. We don't just assume; we test with your actual stock.

Or perhaps your biggest headache is short runs. You need to produce 5,000 boutique cosmetic buckets one day and 50,000 noodle bowls the next. Quick changeover is critical. Our focus shifts to showcasing the tooling swap system. We might design custom, quick-release mandrels and dies for your most common sizes, turning a traditionally grueling four-hour process into a 30-minute task. We think in terms of your operator's experience, designing the automatic paper cup machine controls to be intuitive, reducing training time and error potential.

The customization extends to the container itself. Do you need an extra-wide flange for a secure lid? A unique profile for brand recognition? Reinforced base for stacking heavy frozen products? Our design team collaborates with you, running simulations before a single piece of metal is cut. This consultative approach ensures the paper container forming system isn't just dropped at your loading dock. It's seamlessly integrated into your workflow, solving your specific problems from day one.

Cost Savings and Brand Value Analysis

Let's talk numbers, but let's talk about all the numbers. The initial investment in a Discover Intelligent Paper Bucket Former is, of course, a factor. But the true calculation is in Total Cost of Ownership (TCO) and Return on Investment (ROI). The savings are multifaceted.

Direct Operational Savings:

-

Labor: One automated line can replace 4-6 manual forming stations. This doesn't mean layoffs; it means redeploying skilled labor to quality control, logistics, or machine oversight.

-

Material Waste: Intelligent monitoring cuts defect rates from a typical 5-8% down to below 1.5%. When you’re running tons of material, that’s a staggering direct saving on your most significant variable cost.

-

Energy: Modern servo-drives and efficient heating systems consume far less power than old hydraulic or constantly-running motor systems.

-

Downtime: Predictive maintenance and quick changeovers maximize your asset's productive hours.

Indirect & Strategic Value:

This is where it gets exciting. The sustainable packaging you produce becomes a powerful marketing asset. You can now answer "yes" to the retailer requesting compostable packaging. You can secure the contract with the eco-conscious food brand. You can add a "Made from Recycled Paperboard" badge to your own products, enhancing your brand's reputation. This isn't a soft metric; it translates to market share, price premiums, and customer loyalty. In a survey by Trivium Packaging, 74% of consumers said they would pay more for sustainable packaging. Your paper bucket machine isn't just a cost center; it becomes a brand-value generator.

Engineering Excellence and Peace of Mind

In my two decades watching this industry evolve, I've seen a shift from pure hardware to holistic solutions. The most advanced machine in the world is a paperweight without the right support. This is the intangible that often gets lost in spec sheets.

When you choose Discover, you’re not just buying a machine; you’re gaining a partner. I remember a client, a family-run dairy, terrified of a complex installation halting their peak season production. Our team didn’t just install; we planned a phased integration over a weekend, with our lead engineer on-site the entire first production week. He didn't just fix issues; he broke bread with the operators, learning their rhythms and tweaking the interface to match their logic. That machine didn't just run; it became theirs. The relief on the factory manager's face—that’s the outcome you can't quantify but is absolutely real.

It’s the peace of mind from 24/7 remote diagnostics support. It’s the confidence from a comprehensive parts and training program. It's knowing that the company behind your sustainable packaging equipment is invested in your success, because your growth on this sustainable path is our shared future. We're not in the business of selling units; we're in the business of enabling transformations.

What's Next? The Future Trends in Paper-Based Packaging

Looking ahead, the intelligent paper bucket machine is just the beginning. We're already integrating more AI-driven vision systems for 100% inline quality inspection, rejecting any imperfect container before it ever reaches a packing station. The future points towards even greater material flexibility, handling not just paperboard but new, bio-based composites with ease.

The goal is the "lights-out" packaging line: a fully automated, self-optimizing system that receives a digital order, pulls the correct recycled paper grade, forms, prints, and packs the customized containers, with all data flowing into your ERP system. It’s a seamless, sustainable, and astonishingly efficient flow. By investing in an intelligent system today, you're not just keeping up; you're building a platform ready for that next leap.

The trend is undeniable. The technology is proven. The question is no longer if you should transition to smarter, more sustainable packaging production, but how and with whom.

Ready to see the difference intelligence makes? Let's move from theory to your production reality. [Contact Discover Packaging Solutions today to schedule a virtual demo and a customized ROI analysis for your operation]. Let's build the future of your packaging, together.