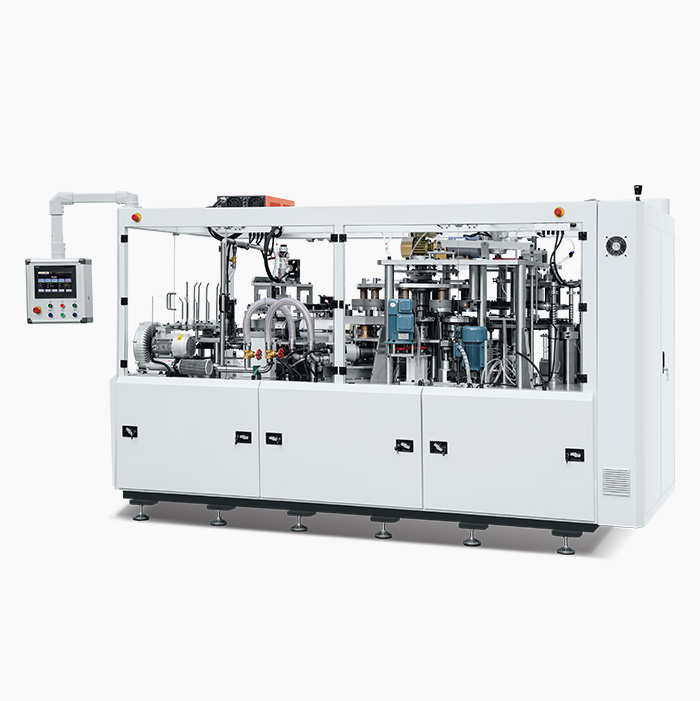

Control system

Operators can set various parameters such as production speed, temperature, pressure, etc. through the control panel. The control system can also monitor the running status of the machine in real time, and in case of failure, it can send out an alarm and display fault information in time, which is convenient for maintenance personnel to troubleshoot.

Crimping mold

It is used to curl the upper mouth of the paper cup. The shape and size of the crimping die need to match the mouth of the paper cup, and by applying pressure, the paper is rolled smoothly. The quality of these parts directly affects the curling effect of the mouth of the paper cup, such as the flatness and tightness of the curling.

Fan-shaped piece feeding

The paper feeding mechanism discharges the fan-shaped sheet on the paper supply holder through the suction cup, and the conveying mechanism then sends the fan-shaped sheet to the next process

The bottom of the cup is formed

Through the web automatic feeding device and the circular punching mechanism, the bottom of the cup is punched and formed; After the bottom of the cup body is preheated and heated, the bottom of the cup is sealed with the cup body by the bottom rolling device.

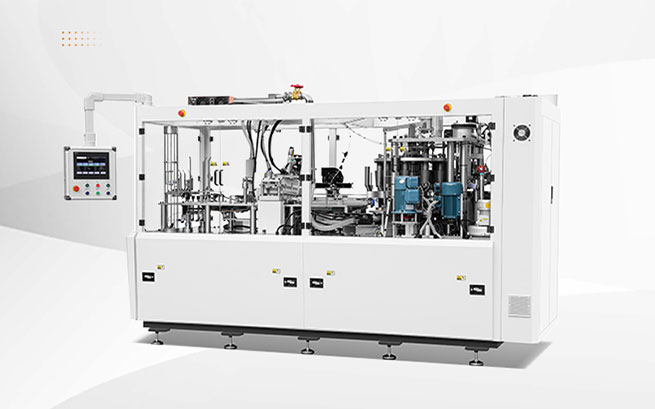

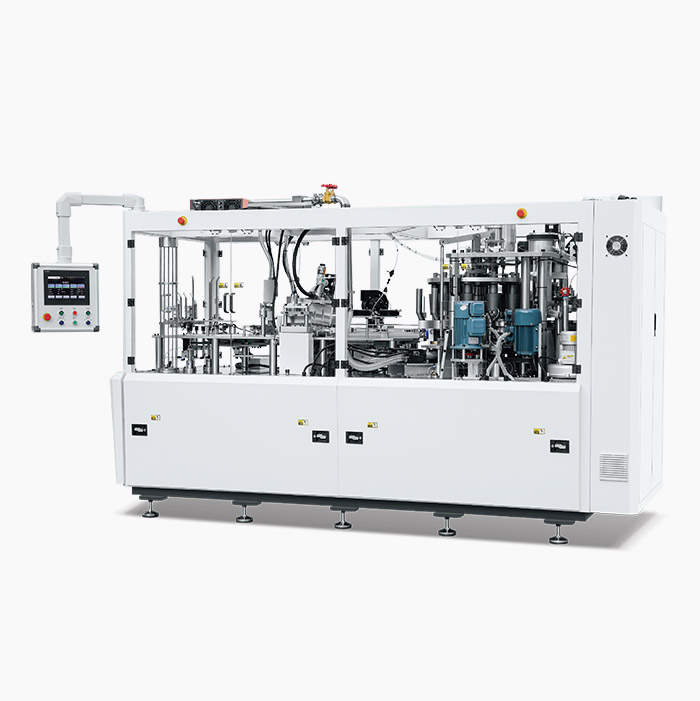

High-Speed and Stable Production

The KSJ-120E is engineered for efficiency, delivering a stable and high-speed operation that ensures smooth cup production. With its precision-driven mechanism, manufacturers can achieve a consistent output with minimal downtime, making it a preferred choice for paper cup making machine manufacturers.

Fully Automated Operation

From paper feeding and sealing to bottom punching and cup stacking, the machine operates with full automation. This reduces manual labor, increases productivity, and enhances operational safety.

Versatile Cup Size Compatibility

The machine supports various cup sizes, making it suitable for manufacturing a wide range of disposable cup making machine products. Its flexibility allows businesses to cater to different market demands with ease.

Precision Sealing and Crimping Technology

A robust ultrasonic sealing system ensures leak-proof and durable cup seams, while the advanced crimping mold guarantees a smooth and strong rim. This results in high-quality paper cups that meet industry standards.

Energy-Efficient and Cost-Effective Design

With an optimized power consumption system, the KSJ-120E minimizes energy usage while maintaining high production efficiency. This makes it a practical choice for businesses looking for a paper cup making machine low price without compromising performance.

Competitive Pricing with Long-Term Benefits

At Discover Machinery's, we understand the importance of balancing affordability with quality. The KSJ-120E offers a cost-effective solution for businesses seeking a paper cup making machine low price, delivering long-term savings through reduced material waste, energy efficiency, and low maintenance costs.

Why Choose Discover Machinery's?

As leading paper cup making machine manufacturers, Discover Machinery’s is committed to providing high-quality, precision-engineered solutions for paper cup production. Our machines are designed to enhance efficiency, reduce costs, and meet the evolving demands of the market.

For businesses looking for a disposable cup making machine that delivers reliability, durability, and cost savings, the KSJ-120E Paper Cup Making Machine is the perfect choice. Contact us today to learn more about pricing and customization options.

Request Quote

Request Quote

Product Comparison

Product Comparison